Since the 1980s, there have been five major disputes (so-called lumber wars) between the United States and Canada, interspersed by three different trade agreements.1 The latest dispute, Lumber V, started after the expiration of the 2006 Softwood Lumber Agreement (SLA) in October 2015.2 The U.S. lumber industry petitioned for trade protections shortly thereafter. This report provides background information on the dispute, summarizes the key issues leading to the tensions between the United States and Canada over softwood lumber, and examines current developments in Lumber V.

Background

Softwood lumber, for purposes of this report, is lumber produced from conifer trees. The definition of the term had been an issue leading up to the signing of the 2006 agreement and is discussed more thoroughly in the Appendix. The SLA definition is based on four tariff items under the Harmonized Tariff Schedule of the United States (HTSUS) and includes essentially all traditional softwood lumber items intended for residential construction.3 Because softwood lumber is primarily used for residential construction, repair, and remodeling, the demand for softwood lumber is a secondary demand, derived substantially from the demand for new or remodeled houses and other buildings.4

Both the U.S. and Canadian softwood lumber industries are largely driven by the U.S. housing market in general and the new construction or remodeling market specifically. In the early to mid-2000s, the U.S. and Canadian softwood lumber industries enjoyed a period of prosperity as the residential real estate market boomed. However, the softwood lumber industry began to struggle when the real estate market began to crash in 2007. For example, from 2005 to 2009 the number of new home construction starts declined by 74%.5 Over that same period, the use of softwood lumber in the United States decreased by 41%.6 Further, the number of sawmills (used to process lumber) decreased by 17%, sawmill capacity decreased by 11%, and sawmill production decreased by nearly 30%.7 Since 2010, the U.S. housing and softwood lumber markets have made a modest recovery. New home construction starts have increased annually.8 U.S. consumption of softwood lumber has increased annually since 2009, although it remains well below the rates of the early 2000s and at levels not seen since the early 1990s.9

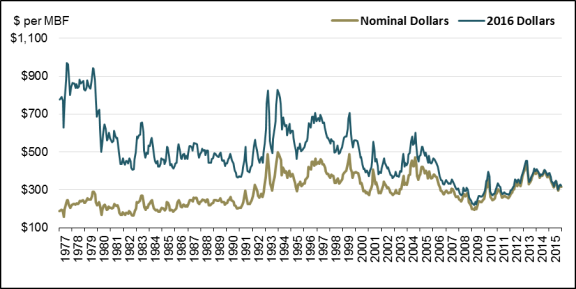

As a secondary demand, softwood lumber is largely price-inelastic. This means that modest changes in construction demand cause relatively large changes in lumber prices, but the price of lumber does not affect the supply or demand of lumber, or, debatably, the price of construction. For example, wood products are generally a minor component of construction costs. While some claim that wood products represent up to 15% of construction costs,10 using the 2014 average framing lumber composite price of $383 per thousand board feet (MBF),11 framing lumber in an average (2,690-square foot) new home would cost $7,512—3% of the 2014 median price of a new home.12 In contrast, the price of lumber dropped significantly as a result of the housing market crash. In 2009, the price of lumber fell below $200 MBF for several months, for the first time since the 1980s (see Figure 1). Since the expiration of the 2006 SLA, lumber prices have risen steadily, and they were above $400 MBF for both March and April 2017. When adjusted for inflation, however, the price of lumber remains relatively low, comparable to the prices of the early 2000s but below prices seen in the 1970s, 1980s, and 1990s in real terms.

Stakeholders in the U.S.-Canada Softwood Lumber Dispute

In the United States, the major stakeholders in the dispute include timber producers (forest land owners), lumber producers, and lumber consumers (homebuilders and home buyers). Timber producers are included with lumber producers, since many lumber producers also own significant tracts of forest land. In Canada, the major stakeholders include the Canadian lumber producers and the provincial governments, as the timberland owners.13

The U.S. lumber producers support trade restrictions on Canadian imports.14 In contrast, U.S. lumber consumers prefer access to affordable lumber and therefore many generally oppose trade restrictions on Canadian imports. The National Association of Home Builders (NAHB), representing the interests of U.S. lumber consumers, contends that American home buyers are the ones who eventually pay for the cost of the trade restrictions and that unrestricted trade benefits the U.S. economy as a whole.15 Further, they maintain that the restrictions have "reduced the incentive for U.S. producers to adopt new and innovative technology to increase production and improve efficiency of their mills so as to be internationally competitive."16 In response to the expiration of the agreement, NAHB and other partners have formed the American Alliance of Lumber Consumers to advocate for trade on lumber.17 However, under U.S. trade remedy laws,18 U.S. lumber consumers do not have standing in the dispute and may only participate as an interested party.19

|

Figure 1. Average Monthly Composite Prices for Framing Lumber in Current (Nominal) and 2016 Dollars |

|

|

Source: Random Lengths Publications, Inc., at http://www.randomlengths.com/ on April 12, 2017. Notes: Adjusted to 2016 dollars using the Consumer Price Index for All Urban Consumers (CPI-U) published by the Bureau of Labor Statistics. MBF = thousand board feet. |

U.S. Softwood Lumber Consumption

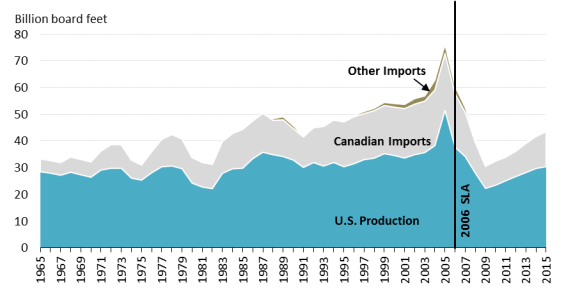

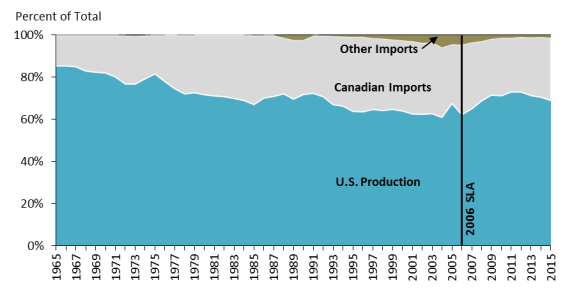

Historically, Canada has been the largest foreign supplier of softwood lumber in the United States, accounting for 95% of imports since 1965 (see Figure 2 and Figure 3).20 In 1965, the United States imported less than 5 billion board feet (BBF) of Canadian lumber, accounting for only 14% of U.S. consumption. However, Canadian imports rose to more than 20 BBF in 2004 and 2005, including an 80% increase from 1990. In comparison, U.S. lumber production for the domestic market (i.e., excluding U.S. lumber exports) during that same period increased by only 56%. The Canadian share of the U.S. market peaked at more than 35% in 1995-1996 and fluctuated around 33% until 2005. Over the nine years the 2006 SLA was in place, the Canadian share of the U.S. market averaged 28% annually.

|

|

Source: Congressional Research Service (CRS); James L. Howard, U.S. Timber Production, Trade, Consumption, and Price Statistics 1965–2002, Res. Pap. FPL–RP–615 (Madison, WI: USDA Forest Service, December 2003), Table 28, p. 52 and Table 31, p. 55. Data update provided via personal correspondence. Notes: Black line indicates when the 2006 SLA was entered in force. |

|

|

Source: CRS; James L. Howard, U.S. Timber Production, Trade, Consumption, and Price Statistics 1965–2002, Res. Pap. FPL–RP–615 (Madison, WI: USDA Forest Service, December 2003), Table 28, p. 52 and Table 31, p. 55. Data update provided through personal correspondence with USDA. Notes: Black line indicates when the 2006 SLA entered into force. |

Alleged Subsidies to Canadian Lumber Producers

The main basis of the United States-Canada softwood lumber dispute is the allegation that Canadian lumber production is subsidized by the Canadian government. U.S. lumber producers allege that these subsidies give Canadian lumber producers an unfair advantage in the U.S. market, causing injury to U.S. producers.21 The U.S. Lumber Coalition, which represents the U.S. lumber industry, has argued that absent a trade agreement or other trade protection measures, Canadian imports have risen due to government programs in Canada.22 In particular, they assert that the fees set by the provinces for government-owned timber are less than prices in a competitive free market in North America would be. However, comparing the relative competitiveness of U.S. and Canadian lumber producers is challenging. This is due to differences in land ownership and thus timber supply, pricing and allocation systems, and measurement systems, among other factors, as described below.

Different Land Ownership and Management Regimes

The United States and Canada both have vast forest resources, but the ownership patterns, development pressures, and forest management policies in each country are very different. In Canada, about 94% of the timberlands are "crown lands" owned and administered by the federal and provincial governments.23 Overall, the provinces own 90% of the timberlands, the Canadian federal government owns 2%, and 6% is in private ownership, although the provincial ownership percentage varies by province. Most of the federally owned timberlands are northern boreal forests located in the Yukon, Nunavut, and Northwest Territories that do not produce significant amounts of softwood lumber. This contrasts with U.S. timberlands, where 42% are owned by the government (31% federal, 9% state, and 2% local) and 58% are privately owned.24 As a result, the United States lumber industry relies more heavily on private timber sources, whereas the Canadian lumber industry relies mostly on public sources of timber.

Each Canadian province has its own forestry laws, regulations, and standards, and Quebec enacted forestry reforms in 2013 in part as an effort to employ the "exit ramp" provisions of the 2006 SLA.25 In general, the provinces require management plans for forested areas, typically prepared by certified professional foresters and subject to participation or review by a broad spectrum of users and interests.26 The provinces also allocate timber harvest. The provinces typically use tenure agreements, or leases, which grant exclusive rights to the specific annual harvest level with various management obligations (e.g., road construction and reforestation).27 The tenure agreements may be long-term (5-25 years) or short-term (as brief as 6 months, with fewer management obligations). Many provinces also have other agreements for selling various types of timber to specific, often quite small or family-operated firms.

|

|

Sources: Map created by CRS using Esri Basemaps. British Columbia Forest Region boundary files were created by Data BC, a pilot project of the British Columbian government, current as of 1/13/2005, at https://apps.gov.bc.ca/pub/geometadata/metadataDetail.do?recordUID=32891&recordSet=ISO19115. Forest cover boundaries provided by the World Wildlife Fund Terrestrial Ecoregions data, current as of 2005. Notes: Province names in dark print were subject to export restrictions in the 2006 SLA; provinces in light print were excluded. |

Different Fee Systems

In large part due to the different land management regimes in the two countries, the United States and Canada each rely on different price allocation systems to determine the cost of lumber. In the United States, prices are established in competitive markets between willing buyers and willing sellers, often through auctions. This is the situation for wood product manufacturers and private timberland owners and, arguably, federal timber sales in areas with competitive bidding.28 Thus, much of the timber from lands in the United States is sold at relatively fair market values. This may not be the case in Canada, where leases (rather than competitive bids) are used to allocate timber.

In Canada, the provinces charge fees for timberland leases and timber harvests. There is generally a flat annual fee for maintaining the leases and a stumpage fee—a per-unit-of-volume fee charged for the right to harvest the trees—for the timber harvested. In many of the provinces, stumpage fees are determined administratively and range from a fixed, province-wide fee to fees established separately for each tenure agreement. These fees are adjusted periodically to reflect changes in the market prices of lumber and other wood products.

As discussed above, while the 2006 SLA was in force, Quebec modified its stumpage pricing systems. In 2013, Quebec passed the Sustainable Forest Development Act,29 which, among other provisions, established that 25% of the annual allowable crown harvest was to be sold at auction starting in 2013. The price received at auction was then factored into the timber agreements covering the remaining 75% of the harvest.

The stumpage fees administered by the Canadian provinces may not match market-determined prices, because the fees are determined by agency personnel who some argue have an incentive to set the fees below market value to assure the competitiveness of their products.30 The U.S. lumber industry asserts that the provinces have intentionally set the fees substantially below market prices, to assure the competitiveness of the Canadian producers.31 Whether provincial administrative stumpage fees approximate market values or are substantially below market values can only be determined by examining provincial fees and U.S. prices for comparable timber, but such comparisons are difficult, as discussed below.

Comparing U.S. and Canadian Stumpage Fees

Allegations that Canadian lumber production is subsidized by the Canadian government rest in part on the claims that Canadian stumpage prices—which are set administratively—are lower than the market-determined stumpage prices in the United States. If this is the case, it would result in a lower cost of production for Canadian firms compared to U.S. firms and might be considered a subsidy from the Canadian government. However, evidence to demonstrate the possible disparity between U.S. and Canadian stumpage fees is widespread, but inconclusive. Some reports have found significantly higher stumpage fees in Canada, while other reports have found the United States to have higher stumpage fees.32 Also, throughout the history of the dispute, the U.S. International Trade Commission (ITC) and the U.S. International Trade Administration (ITA) have found significant differences in stumpage fees in various examinations dating back to 1982. However, other analyses have shown little or no difference between U.S. and Canadian fees.33

Several factors can explain such apparent contradictions. First, U.S. timber and Canadian timber are measured differently. In the United States, trees and lumber are measured in board feet (linear), as described above. In Canada, trees and lumber are measured in cubic meters (volume). The conversion—how many board feet of lumber can be produced from a cubic meter of logs—depends on the diameter of the log, ranging from about 130 board feet per cubic meter for a 6-inch diameter, 16-foot log to more than 275 board feet per cubic meter for a 44-inch, 16-foot log.34 Thus, the conversion rate chosen (i.e., different assumptions about log diameters) can have a significant effect on the resulting price.

Second, except for the occasional forest plantation, forests are not uniform monocultures—forests may contain several species of trees, each of which varies in diameter, height, and quality. U.S. and Canadian forests differ in their species mix (percentage of trees or timber volume in each species) as well as in the size and quality of the trees of each species. Comparisons typically use a single dominant species (e.g., Douglas fir), but the stumpage fee for the dominant species can be affected by the fee for other species. In U.S. federal timber sales, for example, competitive bidding is generally limited to the dominant species, with the other species being sold at the appraised price; this leads to an overall balance, but limits the validity of the fees for comparing the prices of timber in different areas. Adjusting for these differences is difficult, under the best of circumstances.

Other factors also affect stumpage fees. For example, management responsibilities imposed on timber purchasers differ. In Canada, licensees are generally responsible for reforestation and for some forest protection.35 In U.S. federal forests, timber purchasers generally make deposits to pay for agency reforestation efforts, and some of those deposits are typically reported as part of the stumpage fees. Road construction and road maintenance responsibilities and labor compensation also differ.

History of the Dispute

The dispute between the United States and Canada regarding softwood lumber trade dates back to the 1930s, but the so-called lumber wars began in the 1980s when the United States first considered trade protection measures.36 Table 1 summarizes the major periods of trade dispute and agreement from 1982 to the present.

|

Time Period |

Trade Status |

Summary |

|

1982-1983 |

Trade Dispute: Lumber I |

The U.S. lumber industry, represented by the Coalition for Fair Canadian Lumber Imports (CFLI; now known as the U.S. Lumber Coalition), filed a preliminary countervailing duty petition, arguing that the U.S. lumber industry had been harmed by subsidized Canadian provincial stumpage fees. However, the International Trade Administration (ITA) did not establish a countervailing duty. |

|

1986 |

Trade Dispute: Lumber II |

The U.S. lumber industry filed a new countervailing duty petition. In contrast to 1982, the 1986 preliminary finding established a 15% ad valorem countervailing duty, pending a final determination due by December 31, 1986. A final determination was avoided with the signing of a joint Memorandum of Understanding (MOU) between the two countries on December 30, 1986. |

|

1986-1991 |

Trade Agreement: MOU |

The 1986 MOU established a 15% tax on Canadian imports until the Canadian provinces raised stumpage fees. The MOU lasted six years. |

|

1992-1995 |

Trade Dispute: Lumber III |

Canada withdrew from the MOU and the United States imposed another countervailing duty (6.51% ad valorem) shortly thereafter. The United States and Canada filed competing claims against each other in U.S. and international courts for trade violations. |

|

1996-2001 |

Trade Agreement: 1996 Softwood Lumber Agreement |

The United States and Canada signed a five-year Softwood Lumber Agreement that established a fee on imports exceeding a specified quota. |

|

2001-2005 |

Trade Dispute: Lumber IV |

Immediately following the expiration of the 1996 agreement, the United States again imposed countervailing and antidumping orders on Canadian lumber imports (Lumber IV). Again, both countries initiated proceedings in international and U.S. courts claiming violations of various trade agreements, including the North American Free Trade Agreement (NAFTA) and the World Trade Organization (WTO) agreements. The lawsuits persisted until the 2006 Softwood Lumber Agreement was entered in force. |

|

2006-2015 |

Trade Agreement: 2006 Softwood Lumber Agreement |

The United States and Canada signed a six-year Softwood Lumber Agreement that established a system of fees and quotas on Canadian imports. In 2012, the agreement was extended through October 12, 2015. The agreement expired on October 12, 2015, and included a one-year grace period that precluded any trade-protection petitions. |

|

2016 |

Trade Dispute: Lumber V |

After the expiration of the grace period in October 2016, the U.S. lumber industry filed a new countervailing duty petition. A preliminary determination imposed countervailing duties of 20% on Canadian lumber imports on April 24, 2017. A final determination is due by September 2017. |

Source: CRS.

Lumber IV and the 2006 Softwood Lumber Agreement

Between 2001 and 2006, the United States collected approximately $5.3 billion from duties on Canadian lumber (Lumber IV).37 Duty collection and related litigation was terminated with the signing of the SLA in October 2006.38 Under the agreement, the United States returned about $4 billion that was collected from the duties to the importers of record. The remaining deposits were split evenly between the U.S. lumber industry and jointly agreed-upon initiatives. In exchange, the parties agreed to terminate, or in some cases dismiss, all international and domestic court claims filed by Canada, Canadian producers, the United States, and the U.S. industry. The SLA precluded new cases, investigations and petitions, and actions to circumvent the commitments in the agreement and included an agreement by which the participating U.S. producers would not file new petitions or investigations for a period of 12 months after the agreement's termination or expiration. The SLA also established a third-party arbitration system to handle any disputes under the agreement.

The SLA established export charges on softwood lumber originating from specific Canadian provinces when the price of lumber fell below $355 per thousand board feet (MBF),39 with the rate charged varying based on the prevailing composite price.40 The export charges were significantly reduced for Canadian producing regions that also agreed to volume restraints, which become increasingly restrictive as the average price dropped.

The SLA was first set to expire in 2013 but included a one-time option to be renewed for an additional two years. Nearly two years prior to the expiration, on January 23, 2012, the United States and Canada both agreed to the two-year extension. The SLA then expired on October 12, 2015, without any formal negotiations for a new agreement between the counties taking place. The U.S. lumber industry identified perceived flaws in the SLA arbitration process and was in favor of letting the agreement expire. The Canadian government and Canadian lumber producers generally have supported free trade but have been amenable to trade agreements that ensure access to the U.S. market.

Lumber V

As mentioned above, the 2006 SLA expired on October 12, 2015, although a one-year cooling-off period prevented trade litigation from being introduced until after October 12, 2016. On March 10, 2016, President Obama and Prime Minister Trudeau announced the start of discussions to "explore all options" regarding the dispute, charging their trade representatives with reporting back within 100 days.41 The result of this exercise was a set of negotiating goals, which included, among other elements:

- "an appropriate structure, designed to maintain Canadian exports at or below an agreed U.S. market share to be negotiated, with the stability, consistency and flexibility necessary to achieve the confidence of both industries;

- provisions for regional or company exclusions, if justified; and

- provisions promoting regional policies that eliminate the underlying causes of trade frictions, including a regional exits process that is meaningful, effective and timely, recognizing that should an exit be granted, it would be reversible if the circumstances justifying the exit change."42

These goals would effectively limit softwood lumber exports to specified market share, but they left for negotiating the method to achieve this end: through a quota system, an export tax, or a combination of both. The goals also reflect the Canadian desire for flexibility by region and the ability to exit out of market share system based on adoption of market pricing. In subsequent talks, the following concepts were discussed:

- Market restraint mechanism: Canada proposed an export tax on its lumber to achieve a certain market share in the United States. Canada also sought provincial flexibility—quota, export tax, or a combination—to achieve the market access goal. U.S. producers have criticized an export tax as not guaranteeing a certain market share; they claim such a tax would only penalize Canadian producers for exporting above target. As such, U.S. producers are in favor of a quota-only system.

- Market Access: The Canadian proposal reportedly is based on a 32% market share. The U.S. producers reportedly sought a 28% share gradually lowered to 22% during the term of an agreement.

- Regional flexibility: Canada also sought continued exclusions for largely private-held timber from the maritime provinces. They also favored a province's ability to exit the market access restraints if it adopts market based systems, as Quebec claims it has done. The previous SLA contained such a provision, which Canada criticized as ineffectual.

These discussions did not make headway during the last months of the Obama Administration and have not been picked up by the Trump Administration to date.

Litigation

The Committee Overseeing Action for Lumber International Trade Investigations or Negotiations (COALITION) petitioned the International Trade Administration (ITA) of the Department of Commerce and the U.S. International Trade Commission (ITC) to initiate antidumping (AD) and countervailing duty (CVD) proceedings against Canadian softwood lumber on November 25, 2016 (see Error! Reference source not found.). Under AD and CVD procedures, ITA must first determine whether the petition has merit and whether further investigation is warranted. ITA decided in the affirmative on December 15, 2016. ITC then determines whether there is a reasonable indication of injury. ITC made a positive determination on January 9, 2017. If ITC had found no reasonable indication of injury, the proceedings would have ended.43

In the next phase, ITA investigated the existence and extent of the unfair trade practice and made preliminary estimates of the dumping or subsidy margins. On April 24, 2017, ITA determined the existence of a subsidy of between 3.02% and 24.12% on five major companies and an "all other" rate of 19.88%. As a result of this decision, U.S. Customs and Border Protection (CBP), in turn, suspended liquidation (i.e., delayed the computation of duties until the proceedings are finished) and required importers to post cash deposits or bonds to cover the potential duties resulting from the estimated subsidy margin. ITA also found "critical circumstances" for some companies, meaning that retroactive duties from 90 days prior to the preliminary determination will be imposed on them.

The ITA made its preliminary dumping determination on June 26, 2017. Preliminary dumping margins were assessed at 4.59%-7.72%, depending on the company, with an all-other rate of 6.87%, and CBP suspended liquidation to account for these duties. ITA found critical circumstances for companies subject to the all-other rate, thus retroactive dumping duties will be applied from 90 days prior to the preliminary determination. It also exempted lumber products made from logs originating in the maritime provinces of Newfoundland and Labrador, Nova Scotia, and Prince Edward Island.44

ITA and ITC are continuing their respective investigations to a final phase. At this time, ITA will make a final determination as to whether dumping or subsidies exist and a final calculation of the subsidy or dumping margin. If the determination is negative, the process will end, the shipments will be liquidated, and the bonds will be returned. If the ITA makes a determination of subsidy or dumping, then the ITC will determine if practices caused "material injury" to the U.S. industry. If it finds that material injury has occurred, ITA will impose a duty order equivalent to the calculated subsidy or dumping margin. If ITC does not find material injury, CBP will liquidate the goods, return the deposits, and end the case.

|

Antidumping Investigation |

Countervailing Duty Investigation |

|

|

Petitions Filed |

November 25, 2016 |

November 25, 2016 |

|

ITA Initiation Date |

December 15, 2016 |

December 15, 2016 |

|

ITC Preliminary Determinations |

January 9, 2017 |

January 9, 2017 |

|

ITA Preliminary Determinations |

June 26, 2017 |

April 24, 2017 |

|

ITA Final Determinations |

September 6, 2017 |

September 6, 2017 |

|

ITC Final Determinations |

October 21, 2017 |

October 21, 2017 |

|

Issuance of Orders |

October 28, 2017 |

October 28, 2017 |

Source: CRS.

Notes: Dates subject to change. ITA = International Trade Administration; ITC = U.S. International Trade Commission.

Issues for Congress

While the softwood lumber litigation plays out, Congress may seek to influence any settlement of the softwood lumber dispute through potential renegotiation of the North American Free Trade Agreement (NAFTA).45 During the campaign and in office, President Trump has vowed to renegotiate or withdraw from NAFTA. However, under Trade Promotion Authority (TPA),46 the President must give advanced notice to Congress for any renegotiation and must consult with Congress before and during the negotiations. This process affords Congress the opportunity to influence and direct the course of negotiations.

In this fashion, Congress may seek to examine several issues relating to a potential future agreement. For example, Members may seek to shape an agreement within the context of NAFTA itself. Congress may seek the removal of export log restrictions as part of any NAFTA package. Some Members of Congress favor the removal of the NAFTA Chapter 19 dispute settlement arbitration panels, which Canada has used to challenge the decisions of the U.S. agencies. Congress also may consider the extent to which U.S. home builders and home buyers are affected by the possibility of renewed antidumping and countervailing duties being placed on softwood lumber.

Summary and Conclusion

The end of the 2006 SLA and the commencement of trade remedy litigation is a recurring pattern in the decades-long softwood lumber dispute. The determination of injury from subsidy and dumping likely will be followed, as it has in the past, by Canadian appeals to the World Trade Organization and NAFTA dispute settlement. Then, the parameters of a new export restraint agreement may be explored.

U.S. lumber producers assert that they have been injured by Canadian subsidies that have given Canadian lumber producers an unfair advantage in selling lumber in the U.S. market. These two conditions—subsidies and injury—are prerequisites for a countervailing duty under U.S. trade law. One alleged subsidy is Canadian provincial stumpage fees (fees for the right to harvest trees), which may be less than the value of the timber in a competitive market. In the 10 Canadian provinces, 90% of the timberland is owned by the provinces. The majority of provincial timber is allocated to lumber producers under long-term area-tenure agreements, which specify harvest levels, management requirements, and stumpage fees. The stumpage fees generally are set administratively and adjusted periodically to reflect changes in lumber markets. This situation contrasts with that in the United States, where most timberlands are privately owned and timber from federal and state lands typically is offered for sale at competitive auctions. Administered fees are not likely to match market values but could be higher or lower, depending on the purpose and methods by which they are established; critics have claimed that the Canadian administrative fees are set low to assure profitable production, regardless of market conditions. Several studies have shown significantly lower Canadian stumpage fees, but other studies have found comparable cross-border prices. These contradictory results may be explained by the adjustments made to account for differences in timber measurement systems (one cubic meter of Canadian logs yields 125–275 board feet of U.S. lumber, depending on the logs' diameters); in tree species, sizes, and grades; and in requirements imposed on the timber purchaser (e.g., reforestation and road construction), among other factors. Analyses of the differences are difficult and generally problematic.

Injury to the U.S. lumber industry remains a complex issue. The Canadian share of the U.S. softwood lumber market grew substantially over the past 60 years, from less than 7% in 1952 to more than 35% in 1996. During that period, U.S. lumber production for domestic consumption grew slowly (from nearly 30 billion board feet [BBF] in the early 1950s to 35 BBF in 1999), while imports of Canadian lumber rose substantially (from less than 3 BBF in the early 1950s to more than 18 BBF in 1999). Under the 1996 agreement, imports remained at a relatively stable rate, fluctuating around 33%-34%. Under the 2006 SLA, Canadian imports declined to around 28%. This decline is likely attributable—at least in part—to the SLA and a drastically decreased demand for softwood lumber due to the crisis in the U.S. housing market.

Other factors might also be important in the dispute over lumber imports from Canada. Some believe the persistence of the dispute is due, at least in part, to the conflict between a U.S. trade policy focused on the removal of trade barriers and the process for obtaining industry protection under U.S. trade law. Others contend that the dispute is fueled by interest-group politics, and that the U.S. lumber industry is better organized and more influential than U.S. lumber consumers, who mostly feel the cost impacts of the trade protection measures.47 In addition, environmental laws and policies may differ, and the impact of those laws and policies for lumber production costs complicates any cross-border analyses. Finally, the dispute may be alleviated in part due to increasing cross-border firm integration.48 In other words, lumber producers may increasingly become globalized, with holdings in both the United States and Canada, and as such may begin to question these border protection measures.

Appendix. What Is Softwood Lumber?

The definition of "softwood lumber" subject to the SLA had been an issue leading up to the signing of the 2006 agreement.49

Softwood is a classification of tree species and contrasts with the other major classification, hardwood. Both, however, are misnomers. Some hardwoods, "such as aspen and poplar, are softer (less dense) than many softwoods," such as yellow pines.50 Softwood species are all in the order Coniferales—the conifers. Conifers generally have needle-like leaves and cones for reproduction. These plants are often called evergreens, because most retain their needles in winter.51 The hardwood timber species are in the phylum Anthophyta—the angiosperms, or flowering plants. These plants are often called deciduous, because most species in temperate climates lose their leaves in the winter; however, some temperate-climate species (e.g., holly) and most tropical and subtropical species are evergreen, retaining their leaves throughout the year. Despite the imprecision, softwood is the term of art for conifer species and is used in this report to indicate lumber produced from conifer species. This use is also consistent with the definition of softwood lumber in the harmonized tariff schedules and in the 2006 SLA. (See below.)

Lumber is the collective term for products sawn from logs. This contrasts with the panel products—plywood, particleboard, etc.—where the logs are sliced, peeled, or chipped and the wood pieces are then glued together to form sheets or panels.52 It also contrasts with paper products, where wood chips are dissolved to remove the lignin and the fibers adhere by being pressed together under heat. Lumber is grouped into different categories based on cross-sectional dimensions. Boards are lumber products of less than 2 inches in nominal thickness—typically 1 inch thick and 1 inch to 12 inches wide (in 2-inch increments).53 Dimension lumber are products of 2 inches to 5 inches in nominal thickness—most commonly 2 inches thick and 2 inches to 12 inches wide (in 2-inch increments) in nominal dimensions. Timbers are lumber products at least 5 inches thick and wide, and timbers include products destined for further processing. The vast majority of softwood lumber—nearly 75%—is used for residential construction, remodeling, and repair.54

For purposes of the dispute, softwood lumber is defined in Annex 1A of the SLA using four tariff items under the Harmonized Tariff Schedule of the United States (HTSUS):55

Softwood lumber products include all products classified under tariff items 4407.1000, 4409.1010, 4409.1020, and 4409.1090 (for purposes of description only):

coniferous wood sawn or chipped lengthwise, sliced or peeled, whether or not planed, sanded or finger-jointed, of a thickness exceeding 6 mm [about 1/4 inch];

coniferous wood, coniferous wood siding and coniferous wood flooring (including strips and friezes for parquet flooring, not assembled) continuously shaped (tongued, grooved, rebated, chamfered, V-jointed, beaded, moulded, rounded or the like) along any of its edges or faces (other than wood mouldings and wood dowel rods), whether or not planed, sanded or finger-jointed ...56

These tariff items include essentially all the traditional softwood lumber items intended for residential construction, as described above, including softwood drilled and notched lumber and angle-cut lumber and excluding logs, poles, wood fencing, and railway sleepers (cross-ties). The definitions also allow for products that are classified under certain other HTSUS subheadings but meet the SLA's definition of softwood lumber products. This definition also excludes certain products, including windows and doors (with frames), garage doors, box springs, pallets, roof trusses, and other fabricated wood products.