Introduction

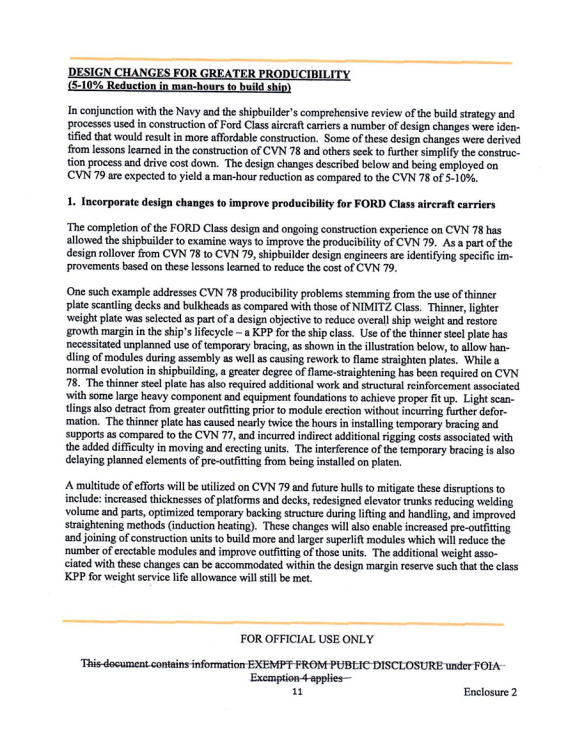

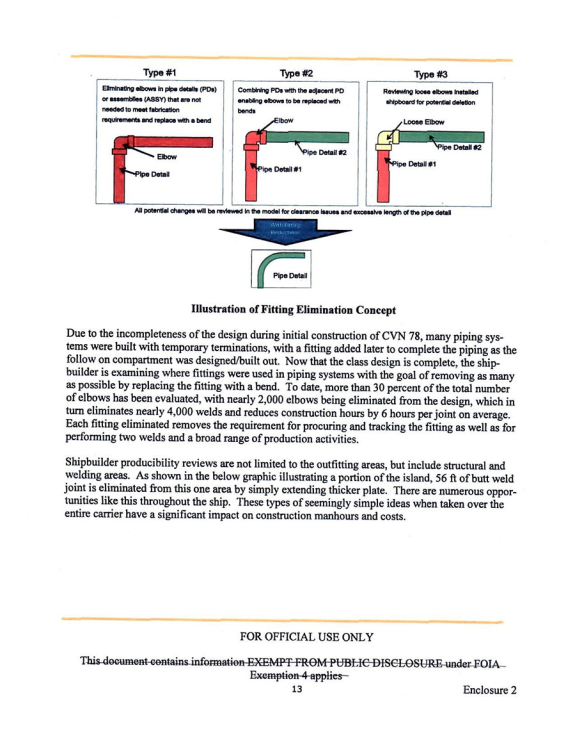

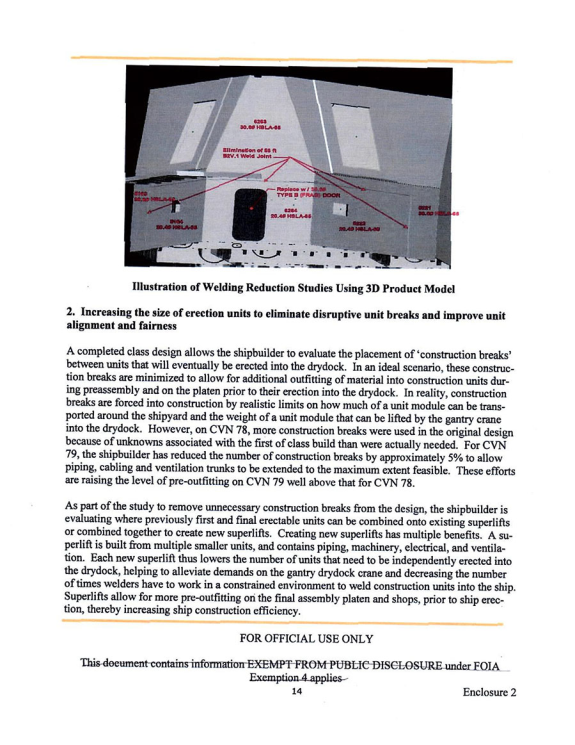

This report provides background information and potential oversight issues for Congress on the Gerald R. Ford (CVN-78) class aircraft carrier program. The Navy's proposed FY2019 budget requests a total of $2,347 million (i.e., about $2.3 billion) in procurement funding for the CVN-78 program. Congress's decisions on the CVN-78 program could substantially affect Navy capabilities and funding requirements and the shipbuilding industrial base.

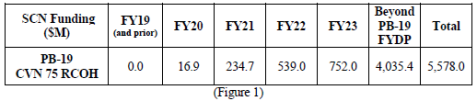

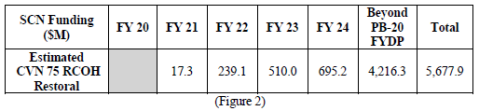

The Navy's FY2020 budget submission also proposed to not fund the mid-life nuclear refueling overhaul (called a Refueling Complex Overhaul, or RCOH) for the aircraft carrier CVN-75 (Harry S. Truman), and to instead retire the ship around FY2024 and also deactivate one of the Navy's carrier air wings at about the same time. On April 30, 2019, however, the Administration announced that it was effectively withdrawing this proposal from the Navy's FY2020 budget submission. The Administration now supports funding the CVN-75 RCOH and keeping CVN-75 (and by implication its associated air wing) in service past FY2024. For additional discussion of this withdrawn budget proposal, see Appendix A.

For an overview of the strategic and budgetary context in which the CVN-78 class program and other Navy shipbuilding programs may be considered, see CRS Report RL32665, Navy Force Structure and Shipbuilding Plans: Background and Issues for Congress, by Ronald O'Rourke.1

Background

Current Navy Aircraft Carrier Force

The Navy's current aircraft carrier force consists of 11 nuclear-powered ships,2 including 10 Nimitz-class ships (CVNs 68 through 77) that entered service between 1975 and 2009, and one Gerald R. Ford (CVN-78) class ship that was commissioned into service on July 22, 2017.3

Statutory Requirements for Numbers of Carriers and Carrier Air Wings

Requirement to Maintain Not Less Than 11 Carriers

10 U.S.C. 8062(b) requires the Navy to maintain a force of not less than 11 operational aircraft carriers.4 The requirement for the Navy to maintain not less than a certain number of operational aircraft carriers was established by Section 126 of the FY2006 National Defense Authorization Act (H.R. 1815/P.L. 109-163 of January 6, 2006), which set the number at 12 carriers. The requirement was changed from 12 carriers to 11 carriers by Section 1011(a) of the FY2007 John Warner National Defense Authorization Act (H.R. 5122/P.L. 109-364 of October 17, 2006).5

Requirement to Maintain a Minimum of Nine Carrier Air Wings

10 U.S.C. 8062(e), which was added by Section 1042 of the FY2017 National Defense Authorization Act (S. 2943/P.L. 114-328 of December 23, 2016), requires the Navy to maintain a minimum of nine carrier air wings.6

Navy Force-Level Goal of 12 Carriers

12-Carrier Goal Established December 2016

In December 2016, the Navy released a force-level goal for achieving and maintaining a fleet of 355 ships, including 12 aircraft carriers7—one more than the minimum of 11 carriers required by 10 U.S.C. 8062(b). This was the first Navy force-level goal to call for 12 (rather than 11) carriers since a 2002-2004 Navy force-level goal for a fleet of 375 ships.8

Planned and Potential Dates for Achieving 12-Carrier Force

Given the time needed to build a carrier and the projected retirement dates of existing carriers, increasing the carrier force from 11 ships to 12 ships on a sustained basis would take a number of years:

- Procuring carriers on 3-year centers—that is, procuring one carrier every three years—would achieve a 12-carrier force on a sustained basis by about 2030, unless the service lives of one or more existing carriers were substantially extended.

- Procuring carriers on 3.5-year centers (i.e., a combination of 3- and 4-year centers) would achieve a 12-carrier force on a sustained basis no earlier than about 2034, unless the service lives of one or more existing carriers were substantially extended.

- Procuring carriers on 4-year centers would achieve a 12-carrier force on a sustained basis by about 2063—almost 30 years later than under 3.5-year centers—unless the service lives of one or more existing carriers were substantially extended.9

Under the Navy's FY2020 30-year shipbuilding plan, as under the Navy's FY2019 30-year shipbuilding plan, carrier procurement would shift from 5-year centers to 4-year centers after the procurement of CVN-82 in FY2028, and a 12-carrier force would be achieved on a sustained basis in the 2060s.

The projected size of the carrier force in the Navy's FY2020 30-year (FY2020-FY2049) shipbuilding plan reflected the Navy's now-withdrawn FY2020 budget proposal to not fund the RCOH for the aircraft carrier CVN-75 (Harry S. Truman), and to instead retire the ship around FY2024. With the withdrawal of this budget proposal, the projected size of the carrier force is now, for the period FY2022-FY2047, one ship higher than what is shown in the Navy's FY2020 budget submission.

The newly adjusted force-level projection, reflecting the withdrawal of the proposal to retire CVN-75 around FY2024, is as follows: The force is projected to include 11 ships in FY2020-FY2021, 12 ships in FY2022-FY2024, 11 ships in FY2025-FY2026, 10 ships in FY2027, 11 ships in FY2028-FY2039, 10 ships in FY2040, 11 ships in FY2041, 10 ships in FY2042-FY2044, 11 ships in FY2045, 10 ships in FY2046-FY2047, 9 ships in FY2048, and 10 ships in FY2049.

Incremental Funding Authority for Aircraft Carriers

Under incremental funding, some of the funding needed to fully fund a ship is provided in one or more years after the year in which the ship is procured. In recent years, Congress has authorized DOD to use incremental funding for procuring certain Navy ships, most notably aircraft carriers:10

- Section 121 of the FY2007 John Warner National Defense Authorization Act (H.R. 5122/P.L. 109-364 of October 17, 2006) granted the Navy the authority to use four-year incremental funding for CVNs 78, 79, and 80. Under this authority, the Navy could fully fund each of these ships over a four-year period that includes the ship's year of procurement and three subsequent years.

- Section 124 of the FY2012 National Defense Authorization Act (H.R. 1540/P.L. 112-81 of December 31, 2011) amended Section 121 of P.L. 109-364 to grant the Navy the authority to use five-year incremental funding for CVNs 78, 79, and 80. Since CVN-78 was fully funded in FY2008-FY2011, the provision in practice applied to CVNs 79 and 80.

- Section 121 of the FY2013 National Defense Authorization Act (H.R. 4310/P.L. 112-239 of January 2, 2013) amended Section 121 of P.L. 109-364 to grant the Navy the authority to use six-year incremental funding for CVNs 78, 79, and 80. Since CVN-78 was fully funded in FY2008-FY2011, the provision in practice applies to CVNs 79 and 80.

- Section 121(c) of the John S. McCain National Defense Authorization Act for Fiscal Year 2019 (H.R. 5515/P.L. 115-232 of August 13, 2018) authorized incremental funding to be used for making payments under the two-ship block buy contract for the construction of CVN-80 and CVN-81. This provision does not limit the total number of years across which incremental funding may be used to procure either ship.

Aircraft Carrier Construction Industrial Base

All U.S. aircraft carriers procured since FY1958 have been built by Huntington Ingalls Industries/Newport News Shipbuilding (HII/NNS), of Newport News, VA. HII/NNS is the only U.S. shipyard that can build large-deck, nuclear-powered aircraft carriers. The aircraft carrier construction industrial base also includes roughly 2,000 supplier firms in 46 states.11

Gerald R. Ford (CVN-78) Class Program

Overview

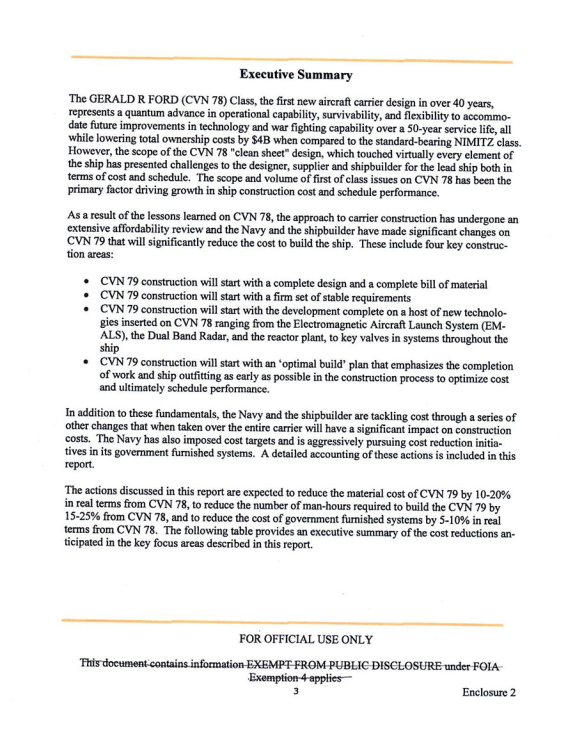

The Gerald R. Ford (CVN-78) class carrier design (Figure 1) is the successor to the Nimitz-class carrier design.12 The Ford-class design uses the basic Nimitz-class hull form but incorporates several improvements, including features permitting the ship to generate more aircraft sorties per day, more electrical power for supporting ship systems, and features permitting the ship to be operated by several hundred fewer sailors than a Nimitz-class ship, reducing 50-year life-cycle operating and support (O&S) costs for each ship by about $4 billion compared to the Nimitz-class design, the Navy estimates. Navy plans call for procuring at least four Ford-class carriers—CVN-78, CVN-79, CVN-80, and CVN-81.

CVN-78 (Gerald R. Ford)

CVN-78, which was named Gerald R. Ford in 2007,13 was procured in FY2008. The Navy's proposed FY2020 budget estimates the ship's procurement cost at $13,084.0 million (i.e., about $13.1 billion) in then-year dollars. The ship received advance procurement (AP) funding in FY2001-FY2007 and was fully funded in FY2008-FY2011 using congressionally authorized four-year incremental funding. To help cover cost growth on the ship, the ship received an additional $1,394.9 million in FY2014-FY2016 and FY2018 cost-to-complete procurement funding. (This $1,394.9 million is included in the above-mentioned estimated procurement cost of $13,084.0 million.) The ship was delivered to the Navy on May 31, 2017, and was commissioned into service on July 22, 2017. The Navy is currently working to complete construction, testing, and certification of the ship's 11 weapons elevators, and to correct other technical problems aboard the ship.

|

|

Source: Navy photograph dated April 8, 2017, accessed October 3, 2017, at http://www.navy.mil/view_image.asp?id=234835. |

CVN-79 (John F. Kennedy)

CVN-79, which was named John F. Kennedy on May 29, 2011,14 was procured in FY2013. The Navy's proposed FY2020 budget estimates the ship's procurement cost at $11,327.4 million (i.e., about $11.3 billion) in then-year dollars. The ship received AP funding in FY2007-FY2012, and was fully funded in FY2013-FY2018 using congressionally authorized six-year incremental funding. The ship is being built with an improved shipyard fabrication and assembly process that incorporates lessons learned from the construction of CVN-78. A key aim of this improved process is to substantially reduce the real (i.e., inflation-adjusted) construction cost of CVN-79 compared to that of CVN-78. CVN-79 is scheduled for delivery to the Navy in September 2024.

Two-Ship Block Buy Contract for CVN-80 and CVN-81

CVN-80 (Enterprise) and CVN-81 (Doris Miller) are being procured under a two-ship block buy contract that was authorized by Section 121(a)(2) of the John S. McCain National Defense Authorization Act for Fiscal Year 2019 (H.R. 5515/P.L. 115-232 of August 13, 2018). The provision permitted the Navy to add CVN-81 to the existing contract for building CVN-80 after the Department of Defense (DOD) made certain certifications to Congress. DOD made the certifications on December 31, 2018, and the Navy announced the award of the contract on January 31, 2019.

Compared to the estimated procurement costs for CVN-80 and CVN-81 in the Navy's FY2019 budget submission, the Navy estimates under its FY2020 budget submission that the two-ship block buy contract will reduce the cost of CVN-80 by $246.6 million and the cost of CVN-81 by $2,637.3 million, for a combined reduction of $2,883.9 million (i.e., about $2.9 billion).15 (DOD characterizes the combined reduction as "nearly $3 billion."16) Using higher estimated baseline costs for CVN-80 and CVN-81 taken from a December 2017 Navy business case analysis, the Navy estimates under its FY2020 budget submission that the two-ship contract will reduce the cost of CVN-80 by about $900 million and the cost of CVN-81 by about $3.1 billion, for a combined reduction of about $4.0 billion.17 These figures are all expressed in then-year dollars, meaning dollars that are not adjusted for inflation.

Regarding the difference between a savings of about $2.9 billion from the figures in the Navy's FY2019 budget submission and a savings of about $3.9 billion from the December 2017 Navy business case analysis, a February 5, 2019, press report quoted a Navy spokesman as stating that the Navy's FY2019 budget submission "already accounted for at least $1B [$1 billion] of potential savings, a two-CVN buy would save an additional $3B [$3 billion]."18 This suggests that the Navy, in preparing its FY2019 budget submission, may have anticipated that it would receive from Congress authority for implementing some kind of combined purchase (such as, perhaps, a combined purchase of materials) for CVN-80 and CVN-81.

For additional background information on the two-ship block buy contract, see Appendix B.

CVN-80 (Enterprise)

CVN-80, which was named Enterprise on December 1, 2012,19 was procured in FY2018. The Navy's proposed FY2020 budget estimates the ship's procurement cost at $12,335.1 million (i.e., about $12.3 billion) in then-year dollars. The ship received AP funding in FY2016 and FY2017, and the Navy plans to fully fund the ship in FY2018-FY2025 using incremental funding authorized by Section 121(c) of P.L. 115-232. The Navy's proposed FY2020 budget requests $1,062.0 million in procurement funding for the ship. The ship is scheduled for delivery to the Navy in March 2028.

CVN-81 (Doris Miller)

On January 20, 2020, the Navy announced that CVN-81 would be named for Doris Miller, an African American enlisted sailor who received the Navy Cross for his actions during the Japanese attack on Pearl Harbor on December 7, 1941.20 Prior to the awarding of the two-ship block buy contract, CVN-81 was scheduled to be procured in FY2023. Following the awarding of the two-ship block buy contract, the Navy chose to show CVN-81 in its FY2020 budget submission as a ship to be procured in FY2020 (as opposed to a ship that was procured in FY2019). The Navy's FY2020 budget submission estimates the ship's procurement cost at $12,450.7 million (i.e., about $12.5 billion) in then-year dollars. The Navy plans to fully fund the ship beginning in FY2019 and extending beyond FY2026 using incremental funding authorized by Section 121(c) of P.L. 115-232. The Navy's proposed FY2020 budget requests $1,285.0 million in procurement funding for the ship. The ship is scheduled for delivery to the Navy in February 2032.

Program Procurement Funding

Table 1 shows procurement funding for CVNs 78, 79, 80, and 81 through FY2026+ (meaning FY2026 and some number of years after FY2026).

Program Procurement Cost Cap

Congress has established procurement cost caps for CVN-78 class aircraft carriers:

- Section 122 of the FY2007 John Warner National Defense Authorization Act (H.R. 5122/P.L. 109-364 of October 17, 2006) established a procurement cost cap for CVN-78 of $10.5 billion, plus adjustments for inflation and other factors, and a procurement cost cap for subsequent Ford-class carriers of $8.1 billion each, plus adjustments for inflation and other factors. The conference report (H.Rept. 109-702 of September 29, 2006) on P.L. 109-364 discusses Section 122 on pages 551-552.

- Section 121 of the FY2014 National Defense Authorization Act (H.R. 3304/P.L. 113-66 of December 26, 2013) amended the procurement cost cap for the CVN-78 program to provide a revised cap of $12,887.0 million for CVN-78 and a revised cap of $11,498.0 million for each follow-on ship in the program, plus adjustments for inflation and other factors (including an additional factor not included in original cost cap).

- Section 122 of the FY2016 National Defense Authorization Act (S. 1356/P.L. 114-92 of November 25, 2015) further amended the cost cap for the CVN-78 program to provide a revised cap of $11,398.0 million for each follow-on ship in the program, plus adjustment for inflation and other factors, and with a new provision stating that, if during construction of CVN-79, the Chief of Naval Operations determines that measures required to complete the ship within the revised cost cap shall result in an unacceptable reduction to the ship's operational capability, the Secretary of the Navy may increase the CVN-79 cost cap by up to $100 million (i.e., to $11.498 billion). If such an action is taken, the Navy is to adhere to the notification requirements specified in the cost cap legislation.

- Section 121(a) of the FY2018 National Defense Authorization Act (H.R. 2810/P.L. 115-91 of December 12, 2017) further amended the cost cap for the CVN-78 program to provide a revised cap of $12,568.0 million for CVN-80 and subsequent ships in the program, plus adjustment for inflation and other factors. (The cap for CVN-79 was kept at $11,398.0 million, plus adjustment for inflation and other factors.) The provision also amended the basis for adjusting the caps for inflation, and excluded certain costs from being counted against the caps.

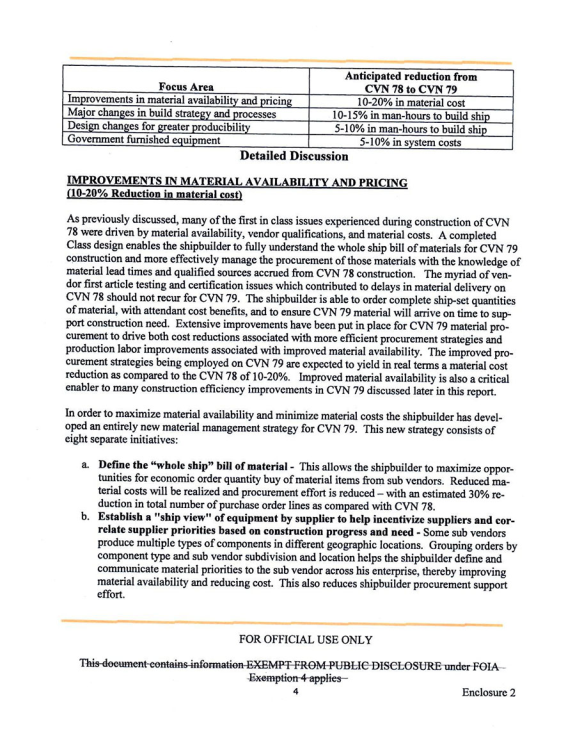

Table 1. Procurement Funding for CVNs 78, 79, 80, and 81 Through FY2026+

(Millions of then-year dollars, rounded to nearest tenth)

|

FY |

CVN-78 |

CVN-79 |

CVN-80 |

CVN-81 |

Total |

|

FY01 |

21.7 (AP) |

0 |

0 |

0 |

21.7 |

|

FY02 |

135.3 (AP) |

0 |

0 |

0 |

135.3 |

|

FY03 |

395.5 (AP) |

0 |

0 |

0 |

395.5 |

|

FY04 |

1,162.9 (AP) |

0 |

0 |

0 |

1,162.9 |

|

FY05 |

623.1 (AP) |

0 |

0 |

0 |

623.1 |

|

FY06 |

618.9 (AP) |

0 |

0 |

0 |

618.9 |

|

FY07 |

735.8 (AP) |

52.8 (AP) |

0 |

0 |

788.6 |

|

FY08 |

2,685.0 (FF) |

123.5 (AP) |

0 |

0 |

2,808.5 |

|

FY09 |

2,684.6 (FF) |

1,210.6 (AP) |

0 |

0 |

3,895.2 |

|

FY10 |

851.3 (FF) |

482.9 (AP) |

0 |

0 |

1,334.2 |

|

FY11 |

1,775.2 (FF) |

902.5 (AP) |

0 |

0 |

2,677.7 |

|

FY12 |

0 |

554.8 (AP) |

0 |

0 |

554.8 |

|

FY13 |

0 |

491.0 (FF) |

0 |

0 |

491.0 |

|

FY14 |

588.1 (CC) |

917.6 (FF) |

0 |

0 |

1,505.7 |

|

FY15 |

663.0 (CC) |

1,219.4 (FF) |

0 |

0 |

1,882.4 |

|

FY16 |

123.8 (CC) |

1,569.5 (FF) |

862.4 (AP) |

0 |

2,555.7 |

|

FY17 |

0 |

1,241.8 (FF) |

1,370.8 (AP) |

0 |

2,612.6 |

|

FY18 |

20.0 (CC) |

2,561.1 (FF) |

1,569.6 (FF) |

0 |

4,150.7 |

|

FY19 |

0 |

0 |

955.2 (FF) |

618.0 (FF) |

1,573.2 |

|

FY20 (requested) |

0 |

0 |

1,062.0 (FF) |

1,285.0 (FF) |

2,347.0 |

|

FY21 (programmed) |

0 |

0 |

1,079.7 (FF) |

1,565.0 (FF) |

2,644.7 |

|

FY22 (programmed) |

0 |

0 |

1,016.6 (FF) |

1,307.0 (FF) |

2,323.6 |

|

FY23 (programmed) |

0 |

0 |

1,169.0 (FF) |

760.0 (FF) |

1,929.0 |

|

FY24 (programmed) |

0 |

0 |

1,051.0 (FF) |

667.0 (FF) |

1,718.0 |

|

FY25 (projected) |

0 |

0 |

2,198.8 (FF) |

696.0 (FF) |

2,894.8 |

|

FY26+ (projected) |

0 |

0 |

0 |

5,552.7 (FF) |

5,552.7 |

|

Total |

13,084.0 |

11,327.4 |

12,335.1 |

12,450.7 |

49,197.2 |

Source: Table prepared by CRS based on Navy's FY2020 budget submission and (for CVN-78 funding figures for FY2010 and FY2011) Navy Office of Legislative Affairs email to CRS dated March 20, 2019, regarding an additional $120 million in reprogrammed funding—$57.3 million in FY2010 and $62.7 million in FY2011—for CVN-78.

Notes: Figures may not add due to rounding. "AP" is advance procurement funding; "FF" is full funding; "CC" is cost to complete funding (i.e., funding to cover cost growth), which is sometimes abbreviated in Navy documents as CTC. FY2026+ means FY2026 and some number of years after FY2026.

In an August 2, 2017, letter to the congressional defense committees, then-Acting Secretary of the Navy Sean Stackley notified the committees that under subsection (b)(7) of Section 122 of P.L. 114-92 as amended by Section 121 of P.L. 113-66—a subsection allowing increases to the cost cap for CVN-78 for "the amounts of increases or decreases in costs of that ship that are attributable solely to an urgent and unforeseen requirement identified as a result of the shipboard test program"—he had increased the cost cap for CVN-78 by $20 million, to $12,907.0 million.

In a May 8, 2018, letter to the congressional defense committees, Secretary of the Navy Richard Spencer notified the committees that under subsections (b)(6) and (b)(7) of Section 122 of P.L. 114-92 as amended by Section 121 of P.L. 113-66—subsections allowing increases to the cost cap for CVN-78 for "the amounts of increases or decreases to cost required to correct deficiencies that may affect the safety of the ship and personnel or otherwise preclude the ship from safe operation and crew certification" and for "the amounts of increases or decreases in costs of CVN 78 that are attributable solely to an urgent and unforeseen requirement identified as a result of the shipboard test program," respectively—he had increased the cost cap for CVN-78 by $120 million, to $13,027 million.21

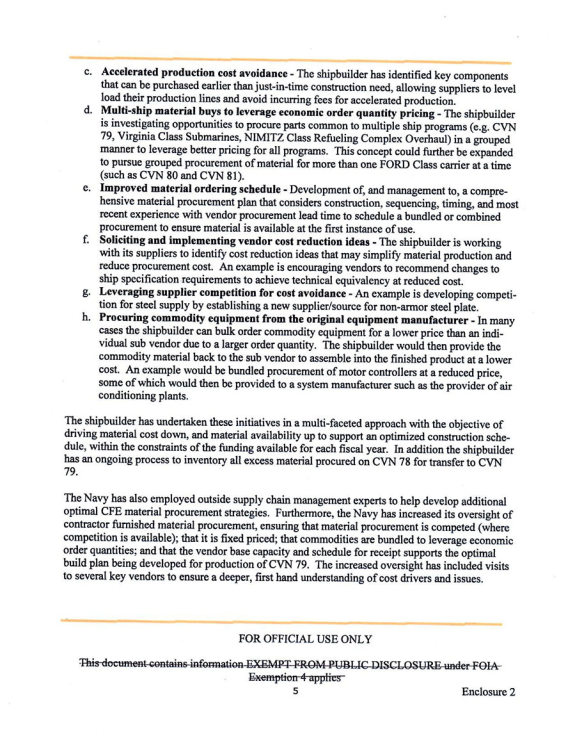

Changes in Estimated Unit Procurement Costs Since FY2008 Budget

Table 2 shows changes in the estimated procurement costs of CVNs 78, 79, 80, and 81 since the budget submission for FY2008—the year of procurement for CVN-78.

Withdrawn Proposal to Not Fund CVN-75 RCOH

The Navy's FY2020 budget submission proposed to not fund the mid-life nuclear refueling overhaul (called a Refueling Complex Overhaul, or RCOH) for the aircraft carrier CVN-75 (Harry S. Truman), and to instead retire the ship around FY2024 and deactivate one of the Navy's carrier air wings at about the same time. On April 30, 2019, however, the Administration announced that it was effectively withdrawing this proposal from the Navy's FY2020 budget submission. The Administration now supports funding the CVN-75 RCOH and keeping CVN-75 (and by implication its associated air wing) in service past FY2024. For additional discussion of this withdrawn budget proposal, see Appendix A.

Issues for Congress for FY2020

Delay in CVN-78's First Deployment Due to Ship's Weapon Elevators and Other Technical Problems

Overview

One oversight issue for Congress concerns a delay in CVN-78's first deployment due to the need to complete the construction, testing, and certification of the ship's weapons elevators and to correct other technical problems aboard the ship.

The ship's 11 weapons elevators—referred to as Advanced Weapons Elevators (AWEs)—move missiles and bombs from the ship's weapon magazines up to the ship's flight deck, so that they can be loaded onto aircraft that are getting ready to take off from the ship. A lack of working weapons elevators can substantially limit an aircraft carrier's ability to conduct combat operations.

Table 2. Changes in Estimated Procurement Costs of CVNs 78, 79, 80, and 81

(As shown in FY2008-FY2020 budgets, in millions of then-year dollars)

|

Budget |

CVN-78 |

CVN-79 |

CVN-80 |

CVN-81 |

||||

|

Est. proc. cost |

Scheduled FY of proc. |

Est. proc. cost |

Scheduled FY of proc. |

Est. proc. cost |

Scheduled FY of proc. |

Est. proc. cost |

Scheduled FY of proc. |

|

|

FY08 |

10,488.9 |

FY08 |

9,192.0 |

FY12 |

10,716.8 |

FY16 |

n/a |

FY21 |

|

FY09 |

10,457.9 |

FY08 |

9,191.6 |

FY12 |

10,716.8 |

FY16 |

n/a |

FY21 |

|

FY10 |

10,845.8 |

FY08 |

n/a |

FY13 |

n/a |

FY18 |

n/a |

FY23 |

|

FY11 |

11,531.0 |

FY08 |

10,413.1 |

FY13 |

13,577.0 |

FY18 |

n/a |

FY23 |

|

FY12 |

11,531.0 |

FY08 |

10,253.0 |

FY13 |

13,494.9 |

FY18 |

n/a |

FY23 |

|

FY13 |

12,323.2 |

FY08 |

11,411.0 |

FY13 |

13,874.2 |

FY18 |

n/a |

FY23 |

|

FY14 |

12,829.3 |

FY08 |

11,338.4 |

FY13 |

13,874.2 |

FY18 |

n/a |

FY23 |

|

FY15 |

12,887.2 |

FY08 |

11,498.0 |

FY13 |

13,874.2 |

FY18 |

n/a |

FY23 |

|

FY16 |

12,887.0 |

FY08 |

11,347.6 |

FY13 |

13,472.0 |

FY18 |

n/a |

FY23 |

|

FY17 |

12,887.0 |

FY08 |

11,398.0 |

FY13 |

12,900.0 |

FY18 |

n/a |

FY23 |

|

FY18 |

12,907.0 |

FY08 |

11,377.4 |

FY13 |

12,997.6 |

FY18 |

n/a |

FY23 |

|

FY19 |

12,964.0 |

FY08 |

11,341.4 |

FY13 |

12,601.7 |

FY18 |

15,088.0 |

FY23 |

|

FY20 |

$13,084.0 |

FY08 |

11,327.4 |

FY13 |

12,335.1 |

FY18 |

12,450.7 |

FY20 |

|

Annual % change |

||||||||

|

FY08 to FY09 |

-0.3 |

0% |

0% |

n/a |

||||

|

FY09 to FY10 |

+3.7 |

n/a |

n/a |

n/a |

||||

|

FY10 to FY11 |

+6.3 |

n/a |

n/a |

n/a |

||||

|

FY09 to FY11 |

+26.7% |

|||||||

|

FY11 to FY12 |

0% |

-1.5% |

-0.1% |

n/a |

||||

|

FY12 to FY13 |

+6.9% |

+11.3% |

+2.8% |

n/a |

||||

|

FY13 to FY14 |

+4.1% |

-0.6% |

0% |

n/a |

||||

|

FY14 to FY15 |

+0.5% |

+1.4% |

0% |

n/a |

||||

|

FY15 to FY16 |

0% |

-1.3% |

-2.9% |

n/a |

||||

|

FY16 to FY17 |

0% |

+0.4% |

-4.2% |

n/a |

||||

|

FY17 to FY18 |

+0.2% |

-0.2% |

+0.7% |

n/a |

||||

|

FY18 to FY19 |

+0.4% |

-0.3% |

-3.0% |

n/a |

||||

|

FY19 to FY20 |

+0.9% |

-0.1% |

-2.1% |

-17.5% |

||||

|

Cumulative % change through FY20 |

||||||||

|

Since FY08 (CVN-78 year of proc.) |

+24.7% |

+23.2% |

+15.1% |

n/a |

||||

|

Since FY13 (CVN-79 year of proc.) |

+6.2% |

-0.7% |

-11.1% |

n/a |

||||

|

Since FY18 (CVN-80 year of proc.) |

+1.4% |

-0.4% |

-3.0% |

n/a |

||||

Source: Table prepared by CRS based on FY2008-FY2020 Navy budget submissions. n/a means not available.

Notes: The FY2010 budget submission did not show estimated procurement costs or scheduled years of procurement for CVNs 79 and 80. The scheduled years of procurement for CVNs 79 and 80 shown here for the FY2010 budget submission are inferred from the shift to five-year intervals for procuring carriers that was announced by Secretary of Defense Gates in his April 6, 2009, news conference regarding recommendations for the FY2010 defense budget.

Challenges in completing the construction, testing, and certifying CVN-78's weapon elevators were first reported in November 2018, and the issue has been a matter of continuing oversight attention since then. The Navy has struggled since November 2018 to meet promises it has repeatedly made to the defense oversight committees to get the elevators completed, tested, and certified. For much of 2019, the Navy continued to report that 2 of the 11 weapon elevators were completed, tested, and certified.22 On October 23, 2019, the Navy reported that the figure had increased to 4 of 11.23

In addition to challenges in building, testing, and certifying the ship's weapon elevators, the Navy reportedly has been working to address problems with other systems on the ship, including its propulsion and electrical systems. Technical issues regarding the weapon elevators and other ship systems have delayed the ship's first deployment to 2022 at the earliest, which would be about five years after the ship was commissioned into service.24 The delay in the ship's first deployment is lengthening a period during which the Navy is attempting to maintain policymaker-desired levels of carrier forward deployments with its 10 other carriers—a situation that can lead to operational strains on those 10 carriers and their crews.

Potential Oversight Questions

Potential oversight questions for Congress include the following:

- Why did the Navy accept delivery of CVN-78 from the shipbuilder and commission the ship into service if most or all of its weapon elevators were not completed, tested, and certified?

- What steps has the Navy taken since CVN-78 was delivered to the Navy on May 31, 2017, to keep Congress informed of challenges regarding the ship's weapon elevators and other ship systems?

- Why is it taking so long to complete, test, and certify the weapon elevators?

- How much is it costing to complete, test, and certify the weapon elevators, and will the Navy include this cost in the ship's total reported procurement cost?

- When will the ship start its first deployment, and how much of a delay will that represent compared to the ship's original schedule for starting its first deployment?

- How much additional operational stress is the delay in CVN-78's first deployment placing on the Navy's 10 other aircraft carriers?

- What steps is the Navy taking to ensure that a similar situation does not arise regarding the construction and initial deployments of CVN-79, CVN-80, and CVN-81?

Press Reports

An October 22, 2019, press report states:

USS Gerald R. Ford (CVN-78) may not be ready to deploy until 2024, further complicating the Navy's persistent problems of generating deployable carriers from the East Coast.

Ford's originally planned deployment date was 2018, but that timeline has continued to slip due largely to developmental delays in the new technologies that were included aboard the first-in-class nuclear aircraft carrier. The delays are also in part due to the Department of Defense's decision for Ford to undergo full-ship shock trials before its first deployment.

The news of the later deployment date came during a Tuesday House Armed Services readiness subcommittee hearing in an exchange between Naval Sea Systems Command head Vice Adm. Tom Moore and Rep. Elaine Luria (D-Va.).

"The original deployment was 2018 and best estimates we're looking at 2024?" Luria asked Moore during the hearing.

"I think we'll beat that," Moore said. "We're going to pull back as far to the left [i.e., earlier] as we can, but I think we're going to beat that."

The initial estimated deployment date is still under review, pending a decision by Chief of Naval Operations Adm. Mike Gilday in consultation with Moore and James Geurts, assistant secretary of the Navy for research, development and acquisition, Geurts told reporters following the hearing.

"I want to make sure the new CNO has got an opportunity to review that plan and make sure he and I are both comfortable with it," Geurts told USNI News after the hearing.25

An October 23, 2019, press report states:

Navy Secretary Richard Spencer defended the long-delayed USS Gerald R. Ford aircraft carrier Wednesday [October 23] and shot back at critics, suggesting that pointed remarks on Capitol Hill Tuesday amounted to "disinformation."

"The ship will be ready to serve and do what it's going to do in the time that the CNO thinks is appropriate, and it's going to be sooner than 2024," Spencer told an audience at the Brookings Institution, referring to Chief of Naval Operations Adm. Michael Gilday. That's the latest estimate for when the Ford will deploy for the first time.

The carrier was originally scheduled to be able to deploy in 2018. Former Navy officer Rep. Elaine Luria (D-Va.) offered a blistering criticism of the delays Tuesday [October 22], calling the vessel a "$13 billion nuclear-powered floating berthing barge" during a hearing with Vice Adm. Thomas Moore of Naval Sea Systems Command and Assistant Secretary of the Navy for Research, Development, and Acquisition James Geurts.

"I look at her and other leadership on the Hill who continually disparage the Ford as a program and I get a little angry," Spencer said, noting that the 2024 date refers to when the carrier's air wing will be aboard and certified for operations, not when the warship itself will be ready. The carrier will be "sent to the fleet much earlier than that," he said.

"You could not ask for a better disinformation program for our competitors" than criticism from congressional critics that underplays the Ford's potential, he added.

"We're going to work this out," Spencer continued, calling the carrier an "efficiency game-changer" and emphasized that of its 11 weapons elevators, long a sticking point for the ship, "this morning we signed elevator No. 4 over" and "elevators 5 and 6 are moving in the ship." Moore and Geurts said Tuesday [October 22] that three of the elevators have been certified for use.26

An October 24, 2019, press report stated:

The plight of the very expensive and very late Gerald R. Ford aircraft carrier ignited a war of words between U.S. lawmakers and Navy leaders this week….

At an event Wednesday [October 23], Navy Secretary Richard Spencer bristled at Luria's criticism of the "massively complex systems" on Ford.

Speaking at a Brookings Institution think tank event, he said such complaints left him feeling that he "could not ask for a better disinformation program for our competitors."

"The way we went to the moon was because the country was behind this, to get us to the moon with new technology," Spencer said. "We're going to work this out."

Ford's innovative high-tech catapults have not only bedeviled engineers trying to perfect them but have also irked President Donald Trump, who said in 2017 that the carrier's electromagnetic system should return to "goddamned steam."

Spencer blamed Congress Wednesday for ever putting a price cap on the carrier, which he likened to making a deal to get your house painted for $100 and then offering the painter only $75.

"I would love to know that Congress understands what a price cap does," Spencer added.

Spencer also laid into [Representative Elaine] Luria for not offering to help.

"I consider that disparaging," he said.

Luria's Capitol Hill team responded that, during Tuesday's hearing, she offered to do just that.

"We want to be here for readiness to provide you the tools to get the carriers out to deploy on time," she told Moore and Assistant Navy Secretary for Research, Development and Acquisition James Geurts. "What else do you need to do that?"

On Wednesday, Spencer also denounced how lawmakers—who he refers to as his "board of directors"—only blame the Navy for the Ford's failures.

"I love the fact that…Congress turns around and says, 'Navy, this is your fault,'" he said. "I have an extra seat up there when I testify, and I have not seen Huntington Ingalls-Newport News called up on the Hill to testify on the outrage my board of directors sees on the Ford."

In a statement released Wednesday night, Luria said she was disappointed that Spencer "finds Congressional oversight disparaging."

"Here are the facts: The USS FORD will be six years delayed in its initial deployment, which causes incredible strain on the carrier fleet," she said.27

An October 27, 2019, press report stated:

The Navy was kept in the dark by Huntington Ingalls' leadership about the severity of engineering issues with Advanced Weapons Elevators on the aircraft carrier Gerald R. Ford according to Navy's top civilian official speaking with reporters Sunday [October 27] at Naval Station Norfolk.

Secretary of the Navy Richard Spencer minced no words after being questioned about the Ford's struggles and recent lawmaker comments about the ship shortly after arriving back ashore from a several hour visit to the ship, which is undergoing trials off the Virginia Coast….

Spencer lauded the work being done on the ship by what he described as an "energized" and "seamless" team of sailors and civilian yard workers working together "to knock down these problems."

His ire, he said, is with leadership at Huntington Ingalls and the shipyard for not communicating the problem up front.

"My issue is with senior management, the board of directors," Spencer said. "I do not believe that we did have an understanding of their understanding of the issue, as translated to us all through the fall [of calendar year 2018)."

The company originally promised the ship' post-shakedown availability would end this past July 15, Spencer said, telling the Navy they were "fairly confident they're going to get all the elevators done."

That forecast changed in March, Spencer said, when "all of a sudden" the shipyard informed the Navy the elevators wouldn't be completed until sometime in 2021 or 2022.

"That was a bit of a gut blow, which questioned in my mind, do they really know what the problem is?" Spencer said and adding "Navy came in and did what we should have done earlier" and "took control of the situation completely as it pertains to the elevator program" and "we got the issues knocked down."

Huntington Ingalls didn't comment directly on Spencer's words, saying instead that the Ford, as a "first-in-class ship" has had "many unique challenges" according to Beci Brenton, spokeswoman for for the company. While "most things have gone very well," she said, "Some of the newer technologies have been more challenging than anticipated.

She echoed Spencers comments saying the company and the Navy have been "working closely" to resolve issues as they arise and praised the efforts of the shipbuilders finding fixes.

"With respect to the advanced weapon elevators, we have four certified elevators turned over to the Navy, and we are on a path to complete the remaining seven in the coming months," she said. "We will continue to support our Navy partner in their preparations for the ship's deployment."

Spencer said he believes the ship and the program have turned a corner in recent months and the worst is behind….

To date, he said, the ship has "seven moving elevators, of which four are certified" and handed over to the ship with "three others that are under various forms of testing."

When asked how long now before the ship is combat-ready, Spencer said "I'll let you know" saying the ship can't become combat ready until she is "given to the Navy" and put through a full work-up cycle.

That's because of necessary milestones in the ship's immediate future, such as "Post Delivery Tests and Trials, Full Ship Shock Trials", and a "Planned Incremental [Maintenance] Availability," which all must happen before the ship can begin working up for deployment, officials told Defense & Aerospace Report this week.

But that work-up and deployment, Spencer said, is "going to be way before 2024, I guarantee you that."…

"The issues with the elevators that we're slaving away with, when we find a fix here is being immediately walked over to the Kennedy [CVN-79]," he said. "I think what you're going to see is learning put into action with Kennedy, and you'll see it out quicker."28

An October 28, 2019, press report stated:

The US Navy's top acquisition official was upbeat as he met with media Monday [October 28] in his Pentagon office. He was just back after a quick trip to the long-troubled aircraft carrier Gerald R Ford (CVN 78), now underway off the Virginia coast on sea trials after 15 months in a shipyard….

[Assistant Secretary of the Navy for Research, Development and Acquisition James Geurts] added that the four operationally-certified elevators are the three upper-stage elevators plus a utility elevator also used for medical evacuations. Seven more lower-stage elevators continue to receive attention, with three of those nearing certification, he said. But it will still be about a year and a half before all 11 elevators are certified and in full operation, he cautioned.

Of the ship's other systems, the Dual Band Radar (DBR), a unique feature on the Ford, "has been up and operating while at sea, tracking targets. Feeling pretty good about that," he said.

Geurts also said he was pleased with progress on the Electromagnetic Aircraft Launch System (EMALS) and Advanced Arresting Gear (AAG), two more key new technologies on the carrier. New elements have been put in place on the arresting gear, he said, and land-based testing of the systems continues at an ever-growing pace. Flight operations on the Ford, he said, should resume shortly after the turn of the year, adding the goal is to work the system hard.

The ship's propulsion system already is being checked out, Geurts noted.

"We've been at full power, we've tested the [main shaft] bearings, we've tested the throttles, everything looks solid," he said, knocking a wooden table while adding the main turbine generators and the propulsion plant also look good.

Geurts expressed confidence that a dispute between HII and General Electric about responsibilities with problems in the ship's propulsion plant will be worked out between the companies, with no additional costs to the Navy….

Asked for examples of where the cost cap might have prevented needed work from being done in a timely fashion, Geurts pointed to "some of the prototyping, some of the risk reduction.

"With a cost cap you can actually cause a behavior that suppresses information," he said. "People don't want to bring bad news to the boss. I'm much more for transparency so you can make decisions.

"I just worry sometimes the intended behavior might not be the resultant behavior," he added. "Cost cap as a management mechanism may not be the best way to drive that."

During the Ford's post-shakedown availability—a planned post-delivery shipyard period where Navy ships return to the yard to correct deficiencies discovered in their initial, shakedown, period and receive additional work—Newport News shipbuilders essentially defined a new shipyard trade of specialists working on the advanced elevators, which will be installed on the Kennedy, Enterprise and all future carriers in addition to the Ford.

"The shipyard has created a kind of trade school for elevators now," Geurts said. "I am pretty optimistic that HII is setting up almost a specific trade, with specific training and a specific focus on this. That work force can now move from ship to ship and kind of be the AWE super geniuses as opposed to having to retrain tradesmen in this rather unique skill."

A full, land-based test site is also being built by the Navy in Philadelphia to further test the technology.

"I think that's where we missed it," Geurts said of the AWE problems on the Ford. "The technology itself is not that exotic. The construction and getting the construction sequence right and having that planned very, very specifically, is what we really learned on 78.

"The other challenge is there isn't a huge degree of commonality between the eleven elevators, so you don't really get as much learning between elevators on the single ship, you get learning on the elevators across a class of ships."29

An October 29, 2019, press report stated that

The Navy's top acquisition official said all the of the delayed advanced weapons elevators (AWEs) on the USS Gerald R. Ford (CVN-78) will be finished and operational by the time an 18-month post-deliver test and trials (PDT&T) period finishes.

Assistant Secretary of the Navy for Research, Development and Acquisition James Geurts told media during a roundtable Oct. 28 that as of Oct. 27, when he and Secretary of the Navy Richard Spencer visited the Ford, it was about 50 percent through its sea trials and is expected back to the naval base by the mid-week.

The carrier first went back to sea for sea trials after finishing its post-shakedown availability (PSA) repair and maintenance period on Oct. 25….

After finishing these trials, it will undergo a nominal 18-month PDT&T period where the crew and air wing will get certified and get the ship ready for carrier strike group workups. Flight operations will start on CVN-78 in the next calendar year to recertify the flight deck, fuel systems and overall prepare for flight operations.

Geurts admitted there is carryover work on the long-delayed elevators, but he was sure they will be finished before the ship is deployed and the Navy-industry team have a better handle on them going forward.

"We do have a little carryover work and so we did work our way through elevators," with four turned over to the crew and seven left to finish installation and certification.

Geurts said the Navy has cycled the finished elevators over 200 times since the Ford started these trials. They are "operating fine at sea and all that but we'll continue to shake those systems out."

He noted shipbuilder and AWE builder Huntington Ingalls Industries [HII' has personnel on board during the trials to work on the seven remaining elevators "proving exactly how to do that while at sea & how to pre-stage equipment the right way."

Geurts said three of the lower elevators are in varying states of final construction and when he visited HII was testing one.

"So we're taking advantage of that and working as an integrated team out there."

Geurts underscored the Navy-HII team's output over the last 90-100 days "has been on a much better path than we were previously and that's why I am cautiously optimistic on both progress to get the rest of the Ford ones done and then be able to accelerate through 79 through 81."

Last week, Spencer said the Navy started making more progress on the AWEs once a service team took over the project but also strongly criticized HII management….

Geurts said the Navy and HII have had to work together "to get the right team focused on elevators. The Navy put a dedicated team down there, HII has recognized we've got to get both build, grow and sustain a dedicated workforce to get after those and be a little bit bolder in our action."…

Geurts explained several risk reduction measures the Navy and HII have undertaken to speed up the elevator work.

Some changes are "design tweaks for producibility." Previously, the AWE door hinges were welded on every time so when you reset the door they had to unweld them and then reposition them.

"It actually was one of the submarine experts came over from HII and looked at it and now kind of moving to movable fittings so you can kind of get the fitting right and then do the welds so you can adjust it easier."

The Navy has also built a full digital twin of the AWE software. "That's already up and running, so we can run the software and get the software stable and test it. And then longer term we're building a land-based test site up in Philly."30

An October 30, 2019, press report stated:

The Secretary of the Navy today said the cost cap on the first Ford-class aircraft carrier helped lead to problems resulting in delays to the advanced weapons elevators (AWEs) and explained the government's issues and changing strategy with the shipbuilder.

Secretary of the Navy Richard Spencer said on Wednesday at a Heritage Foundation press roundtable that the Navy and shipbuilder/AWE builder Huntington Ingalls Industries [HII] planned to build a test elevator site, similar to the electromagnetic advanced landing system (EMALS) located in Lakehurst, N.J.

The Navy has used Joint Base McGuire-Dix-Lakehurst to test the General Atomics advanced arresting gear (AAG) and EMALS [electromagnetic aircraft launch system] hundreds of times before testing them on the first new carrier, the USS Gerald R. Ford (CVN-78).

"Then we had the cost cap come in. And as [HII president and CEO] Mike Petters can say, you know fine, the cost cap comes in and no one builds the land site [weapon] elevator. We had to cut costs somewhere. Sometimes we're our own worst enemy," Spencer said….

Spencer said he thinks about it and wonders if anyone was expecting there to be second and third order effects of a cost cap.

"You don't get anything for free and you're not going to drive quality by cost cap. We have to start thinking differently when we go to cost control."…

On Monday [October 28], Assistant Secretary of the Navy for Research, Development and Acquisition James Geurts said the Navy-HII team's output on the elevators has been much better in the last few months and he was cautiously optimistic on progress of the Ford elevators….

Spencer said in fall 2018 the Navy was finalizing the HII elevator plan. The company gave him a chart that said all 11 AWEs would be tested and certified by the end of the planned post-shakedown availability (PSA), which was then planned for July 15.

He said HII management reported high confidence of this timeline while Naval Reactors told him due to throttle and bearing issues the PSA would likely be pushed into September or October, "so I had more margin there. Did I feel confident? Completely confident."

Then, in January, Spencer said he made a bet with President Trump that the AWEs would be finished with the PSA or he could be fired….

Spencer explained this was meant to rally the shipbuilders.

"What we weren't seeing down there was the spring in the step of the people on the waterfront, to be very frank with you. It was business as usual. So we said ok, here's a rally point, we're going to commit to this."

However, in May 2019 he said HII management "goes oops, here we are, elevators aren't going to be ready until the end of 2020, possibly 2021. And that's when I went, do they really know what they're doing?"

Spencer called that a moment of inflection and called Thomas Fargo, chairman of the board of HII, asking if the board knew what was going on with management "because out trust and confidence on this specific project of the elevators has eroded significantly."

While Spencer said Fargo said yes, there were continued frustrations on the government side.

"That's when Hondo [Geurts] and I said let's get a tiger team down there and let's take this over as the general contractor and HII can sub[contract] to us [i.e., the Navy]. And that's basically what's happened this last 3 months."

Spencer said he went to the president and, after explaining the situation, was told "it's a complex system, keep knocking down the dragons."31

Another October 30, 2019, press report stated that at the press roundtable, Spencer noted that CVN-78 is the first ship in its class:

"It's first of class.… First of class is tough. If I look at what we're doing to [the second-in-class ship, the future John F. Kennedy (CVN-79)], we're down 3.2 million man-hours for where Ford was[, an] 18 percent decrease. You look at what we're doing on the elevators, what we're picking up on—here's a fine example to the way to look at it: on the elevators, one of the problems was we have to get a two-pound pressure differential in each deck on three-ton doors. Well, the way they designed it is you actually have to weld and cut the hinge to adjust it. Well, now we're doing a hanging hinge on Kennedy. So we're taking learning [from CVN-78] to the ship [CVN-79]. I'd be remiss if I'd say that's the last (funding request), to be very frank; I'd rather have the option to say we're going to come for more than to say we're capped off now. I feel good on what we're finally learning on the end of this."32

Another October 30, 2019, press report resulting from the press roundtable stated:

Refusing to backtrack from previous criticisms and admitting anew he has questioned if executives at Huntington "really know what they're doing," Spencer did signal a new detente with a congresswoman [Representative Elaine Luria] he sparred with recently about the Ford class, however….

In a thaw in the relationship however, on Tuesday Luria and Navy acquisition boss James Geurts met in her Capitol Hill office to go over the Navy's plans to fix seven of the ship's 11 electromagnetic weapons elevators. Luria spokesman Chris Carroll told me it was "a positive meeting," adding his boss "still has strong concerns about progress on the Ford." Geurts' spokesman Capt. Danny Hernandez said the Navy would keep conversations with members of Congress private.

Speaking at a breakfast event at the Heritage Foundation today, Spencer sought to play down the feud, telling reporters the back-and-forth was the result of "frustration on both sides" over problems on the Ford, adding he shares her frustration over the ship's problematic technologies and delayed schedule.

Reporting on the status of various systems on the ship, another October 20, 2019, press report stated:

The skipper of the world's most technologically advanced aircraft carrier [Capt. John J. "Yank" Cummings] says the ship has "absolutely" turned the corner and is now ready to work towards full operational status.

After a 15-month stint back in the shipyard where the ship was built, most of its plethora of new technology is now up and running. The ship is now ready to begin advanced trials as the crew and the Navy will now learn how to take Ford's high-tech gear to the next level and earn a spot in the deployment rotation….

Cummings talked to media on board the ship today, moments after their five-day at sea period ended as the ship tied up at Naval Station Norfolk's Pier 11. While underway… nearly all of her ship systems were put to the test, he said, and passed….

The past few days, according to to the Naval Sea Systems Command's Rear Adm. Jim Downey, the man in charge of overseeing the building and maintenance of the Navy's flattop fleet, have proven the ship has finally worked out most of the kinks that have plagued the ship since even before it was commissioned in July of 2017.

"The ship got underway right on schedule on Friday—conducted over 100 events over the the last few days and was very successful overall."

Up and running, he said, is the ship's propulsion system that was put through the full range of testing both forward and backwards and even high-speed turns. There was no sign of the thrust bearing issues that led to breakdowns before the latest overhaul started.

"Throttle control…performed very well, overall," Downey said "All four [main turbine generators] were online all of those fixes were demonstrated at sea."

The navigation system got a workout and combat systems, which features the ship's dual-band radar worked fine through its initial runs where it "tracked multiple targets."

And though all the Advanced Weapons Elevators aren't fully operational, yet, Downey said that all eleven will be operating by the end of the "post delivery testing and trials phase" which is expected to wrap up in the next 18 months.

While at sea, he said, the four elevators now fully operational got a workout while at sea. In addition, a fifth elevator, considered close close to certification was also run constantly and though it's not fully certified, Downey said it "met all its requirements."33

Navy Reporting of Information on Status of CVN-78's Systems

Another potential issue for Congress is whether the Navy has been sufficiently forthcoming in reporting unfinished construction work or technical problems on CVN-78. An October 16, 2019, press report states:

Four major systems in the ship will continue to need work: the Electromagnetic Aircraft Launch System (EMALS), the Advanced Arresting Gear (AAG), the eleven Advanced Weapons Elevators (AWEs) and the Dual-Band Radar (DBR). Issues with those developmental, new-technology systems have been widely reported on for years, ever since Defense Secretary Donald Rumsfeld under the banner of transformation ordered them installed on the first ship in the new class despite deep Navy reservations and recommendations against doing so.

Less talked about are the ship's electrical and propulsion systems. The Ford's more-than-100-megawatt electrical system is far more powerful than the 30 MW systems installed in the ten ships of the previous Nimitz-class carriers, and all that power is crucial to the operation of the four major developmental systems.

The power plant is driven by two new-design nuclear reactors which, by the skimpy information provided to the public, seem to be working fine. But according to numerous sources, there are problems—often unspecified—with the propulsion plant.

One issue that was reported involved the failure of main thrust bearings, fixtures that bear the weight of rotating propeller shafts. Twice, in April 2017 and again in January 2018, the Ford suffered main thrust bearing failures while at sea and was required to head back to port. The Navy did not publicize these problems, which were unknown to the public until Bloomberg's Tony Capaccio reported them in May 2018.

Other reported problems include significant delays with initial sea trials due to issues with voltage regulators on the four main turbine generators. Reports persist that one main propulsion turbine had to be virtually rebuilt after a 2016 accident caused significant damage to its rotors. Some of those accounts add there was serious damage to a second turbine.

It's hard to tell specifically what's going on as Navy and industry decline to go into specifics or to confirm the reports. But the accounts persist, and it could be that one of the most serious problems with the Ford is not up top where the aircraft handling systems and radars are, but deep down in the hull where the propulsion plant lies.

What is abundantly clear is that candor and honesty are not hallmarks of the carrier program—an incredible state of affairs given the enormous cost of the ships and their deep significance to the nation's defense. Quite apart from the very legitimate need for secrecy about classified combat system and propulsion information are fears to disclose even the most mundane details—witness the dearth of photography put out by the service over the ship's initial 81 days at sea. After an initial spate of photos taken when the ship was delivered and commissioned, exceptionally few images have been released to the public—and those that were strained to avoid showing much of the ship, instead focusing on closeups of people aboard her or, if on the flight deck, with an out-of-focus ship's island in the background. This stands in stark contrast to the constant stream of images and videos put out by every other carrier in the fleet when they're in port and underway.

Media would love to photograph and report on the ship, but they're banned from underway visits. At no time during those initial 81 days at sea was any member of any media aboard despite numerous requests to do so. No reporters did standups from the flight deck with the scream of jet engines behind them. No one interviewed sailors on board about what it's like to live and work on such an advanced-technology ship. No ship's captain talked about the wonders of the new systems. No one was allowed to inject the "wow" factor into their reporting—the awe and wonder virtually anyone has the first time they see and ride on a massive aircraft carrier carrying out flight operations at sea.

Why this secrecy? A good question which, when asked, is often met with shuffles and explanations that the ship isn't yet ready, that it would be a distraction, that passenger-carrying aircraft aren't yet qualified to land on the ship….

Professional military people make careers thinking about how to deal with potential enemies, and the history of the US displays no shortfall of bravery, heroism and forthrightness in dealing with the country's foes. But Navy officials are scared and afraid. Afraid of Congressional and governmental oversight, afraid of public criticism, afraid of an informed media, and afraid of each other's internal sniping—which seems to know no end. Senior officials will strongly deny it, but the fear is palpable, quantifiable, widely acknowledged on the inside and obvious from the outside.

Sources say when the Ford renews its trials and development period there will be a heightened sense of urgency and activity. That would be good to see—if the Navy can conquer its fears and lets [sic: let] us.34

Media roundtables and other engagements with the press regarding CVN-78 that the Secretary of the Navy and other senior Navy officials conducted in late October 2019—engagements that produced several of the articles quoted and cited in the previous section regarding challenges with the ship's weapon elevators and other systems—can be viewed as an attempt by the Navy to address the issues regarding the reporting of information on CVN-78 that are raised in the above-quoted passage.

Impact of Continuing Resolution (CR) on CVN-78 Program

Another issue for Congress concerns the impact on the CVN-78 program of funding DOD operations during part of FY2020 under a continuing resolution (CR). Another CRS report provides discusses CR impacts on various Navy shipbuilding programs. As discussed in that report, the following points can be made regarding CR impacts on the CVN-78 program:

- Based on the Navy's FY2020 budget submission—which presents CVN-81 as a ship to be procured in FY2020, rather than a ship was procured in FY2019 (see next section)—the CR's prohibition on increasing a program's procurement quantity would appear to prohibit the Navy from using CR-provided funding for procuring CVN-81, since under the budget submission's presentation, no Ford-class carrier was procured in FY2019, while one is being requested for FY2020. Such an impact could affect not only CVN-81 itself, but more generally the executability of the current two-carrier contract for CVN-80 and CVN-81, which in turn could affect the construction sequence and construction cost of CVN-80.

- If Congress, in marking up the Navy's requested FY2020 budget, decides to treat CVN-81 as a ship that was procured in FY2019, then the CR's prohibition on increasing a program's procurement quantity might have no impact on the CVN-78 program in FY2020. In that case, however, the program could nevertheless be affected by the CR because the amount of procurement funding provided for the program in FY2019 ($1,573.2 million) is equivalent to about 67% of the amount requested for FY2020 ($2,347.0 million).

Navy Decision to Show CVN-81 as a Ship to Be Procured in FY2020

Another issue for Congress concerns DOD's decision to show CVN-81 in its FY2020 budget submission as a ship to be procured in FY2020, instead of a ship that was procured in FY2019. Grounds for showing CVN-81 as a ship that was procured in FY2019 would include the following:

- Within Section 121 of the John S. McCain National Defense Authorization Act for Fiscal Year 2019 (H.R. 5515/P.L. 115-232 of August 13, 2018)—the provision that authorized the two-ship block buy contract for CVN-80 and CVN-81—subsection (a)(1) specifically authorizes a contract for the procurement of CVN-81 "beginning with the fiscal year 2019 program year." The header for subsection (a)(1) is "Procurement Authorized."

- Consistent with Section 121(a)(1), the funding table for the Navy's shipbuilding account in the conference report (H.Rept. 115-874 of July 25, 2018) on H.R. 5515 shows a quantity of "1" in line 002 of the FY2019 SCN (Shipbuilding and Conversion, Navy) appropriation account. Line 002 is the line item for procurement (not advance procurement [AP]) funding for the CVN-78 program. A notation in the table for line 002 states that the procurement funding authorized for this line item is for "Authorize CVN81—One ship."35 The funding table does not authorize any funding for line 003 of the FY2019 SCN account—the line item for AP funding for the CVN-78 program. (AP funding is funding for the procurement of a ship to be procured in a future fiscal year.)

- Consistent with the two above points, the paragraph in the FY2019 DOD appropriations act (Division A of H.R. 6157/P.L. 115-245 of September 28, 2018) that makes appropriations for the SCN account makes procurement (not AP) appropriations for the CVN-78 program. This paragraph also states that "the funds made available by this Act for the Carrier Replacement Program (CVN-80) may be available to modify or enter into a new contract for the procurement of a Ford-class aircraft carrier designated CVN–81 pursuant to section 121 of the John S. McCain National Defense Authorization Act for Fiscal Year 2019."

- Consistent with this bill language, the funding table for the SCN account in the joint explanatory statement for H.R. 6157 shows that this funding was provided for line 2 of the FY2019 SCN account (CVN-78 program procurement funding), not line 3 of the FY2019 SCN account (CVN-78 program AP funding).36

- Consistent with all of the above points (and as reflected in Table 1 of this CRS report), the Navy's FY2020 budget submission shows the $618 million in FY2019 funding for CVN-81 as full funding (meaning funding for a procured ship), rather than AP funding (meaning funding for a ship to be procured in a future fiscal year).37

DOD's decision to show CVN-81 in its FY2020 budget submission as a ship to be procured in FY2020, instead of a ship that was procured in FY2019, affects the comparison of numbers of ships procured in FY2019 and FY2020. If DOD had decided to show CVN-81 in its FY2020 budget submission as a ship that was procured in FY2019, then the total number of ships procured in FY2019 would be 14, and the total number requested for FY2020 would be 11—3 ships, or 21%, fewer than the FY2019 total of 14. Showing CVN-81 in the FY2020 budget submission as an FY2020 ship changes the FY2019 and FY2020 totals to 13 ships and 12 ships, respectively, making number FY2020 closer to the FY2019 number.

DOD's decision to show CVN-81 in its FY2020 budget submission as a ship to be procured in FY2020, instead of a ship that was procured in FY2019, also affects the aircraft carrier procurement profile shown in the Navy's FY2020 30-year (FY2020-FY2049) 30-year shipbuilding plan. If DOD had decided to show CVN-81 in its FY2020 budget submission as a ship that was procured in FY2019, the ship-procurement table in the 30-year plan would show the procurement of no carriers for the first eight years (FY2020-FY2027) of the 30-year period. Showing CVN-81 in the FY2020 budget submission as an FY2020 ship changes the presentation to show the procurement of an aircraft carrier in the first year of the 30-year period.

Potential oversight questions for Congress include the following:

- Compliance with congressional intent. Is DOD's decision to show CVN-81 as a ship to be procured in FY2020, rather than as a ship that was procured in FY2019, consistent with congressional intent as shown in bill and report language for P.L. 115-232 and P.L. 115-245? Can DOD's decision be viewed as a challenge to Congress's Article 1 power to authorize and appropriate funds for the construction of Navy ships? If DOD's decision regarding the year of procurement for CVN-81 is accepted, would this set a precedent for the executive branch regarding its future compliance with Congressional decisions for authorizing and funding of other federal programs?

- Executability of FY2019 procurement funds for CVN-81. FY2019 SCN-account funding for the CVN-78 program was appropriated by Congress, and shows in the Navy's FY2020 budget-justification books, as procurement funding (meaning funding for one or more procured ships) rather than AP funding (meaning funding for one or more ships to be procured in a future fiscal year). If CVN-81 is accepted as a ship to be procured in FY2020, what implications, if any, might that have for the executability of the $618 million in FY2019 procurement (as opposed to AP) funds for CVN-81 shown in the Navy's FY2020 budget submission (as reflected in Table 1 of this CRS report)?

- Executability of CVN-81 during portion of FY2020 under a CR. Navy officials have testified that if the Navy operates under a continuing resolution (CR) for some part of FY2020, then absent a special legislative provision in the CR known as an anomaly, the Navy during that period likely would not be able to proceed with CVN-81, because CRs typically prevent year-to-year quantity increases in procurement programs, and treating CVN-81 as a ship to be procured in FY2020 would mean that the CVN-78 program would have a year-to-year quantity increase of zero ships in FY2019 followed by one ship in FY2020.38 If work on CVN-81 were to not proceed for some part of FY2020 because the Navy during that period were to operate under a CR, what impact would that have on the implementation and status of the two-ship contract for building CVN-80 and CVN-81?

- FY2019 and FY2020 numbers of ships procured and 30-year shipbuilding plan. What effect, if any, did considerations regarding the comparison of numbers of ships procured in FY2019 and FY2020 and the aircraft carrier procurement profile during the initial years of the 30-year shipbuilding plan have on DOD's decision to show CVN-81 in its FY2020 budget submission as a ship to be procured in FY2020, instead of a ship that was procured in FY2019?

- Treatment in FY2020 legislation. Since P.L. 115-232 shows CVN-81 as authorized in FY2019, how should the House and Senate Armed Services committees act on the request in the Navy's FY2020 budget submission to authorize an aircraft carrier in FY2020? If the FY2020 national defense authorization act authorizes the procurement of an aircraft carrier in FY2020, and the authorization for the procurement of an aircraft carrier in FY2019 were not rescinded, would that create confusion as to whether the ship being authorized in FY2020 was CVN-81 or CVN-82, the latter being a ship currently planned for procurement in FY2028? If the FY2019 authorization for CVN-81 were rescinded, what implications, if any, would that have for the implementation of Section 121 of P.L. 115-232, including the award of the two-carrier contract on January 31, 2019 (i.e., during FY2019)?

CVN-82 Not Accelerated from FY2028 to an Earlier Year

Another issue for Congress concerns the Navy's decision, as part of its FY2020 budget submission, to not accelerate the scheduled procurement of CVN-82 from FY2028 to an earlier fiscal year. The Navy's FY2020 budget submission shows that, as a result of the two-carrier contract, the scheduled delivery date for CVN-81 has been accelerated by seven months, to February 2032, compared to September 2032 in the Navy's FY2019 budget submission. The scheduled year of procurement for CVN-82 has not been changed—in the Navy's FY2020 budget submission, it shows as a ship to be procured in FY2028, as it did in the Navy's FY2019 budget submission. The accelerated delivery date for CVN-81, combined with the unchanged year of procurement for CVN-82, suggests that the interval between the construction of CVN-81 and construction of CVN-82 has been increased by something like seven months.

Other things held equal, this increased interval could result in increased loss of learning in shifting from construction of CVN-81 to construction of CVN-82, and possibly in reduced spreading of shipyard fixed overhead costs during the construction of CVN-82. Both of these effects could increase the procurement cost of CVN-82. Potential oversight questions for Congress include the following:

- What impact, if any, will the accelerated delivery of CVN-81 under the two-carrier contract, combined with the unchanged year of procurement for CVN-82, have on the procurement cost of CVN-82?

- How might the procurement cost of CVN-82 change in real (i.e., inflation-adjusted) terms if its year of procurement were accelerated to an earlier year, such as FY2027?

Pricing of Proposed FY2020 Work on CVN-78 Program

Another issue for Congress is whether the Navy has accurately priced the work it is proposing to do on the CVN-78 program in FY2020, particularly in the context of implementing the two-carrier contract for CVN-80 and CVN-81.

Cost Growth and Managing Costs within Program Cost Caps

Overview

For the past several years, cost growth in the CVN-78 program, Navy efforts to stem that growth, and Navy efforts to manage costs so as to stay within the program's cost caps have been continuing oversight issues for Congress on the CVN-78 program.39 As shown in Table 2, the estimated procurement costs of CVN-78, CVN-79, and CVN-80 have grown 24.7%, 23.2%, and 15.1%, respectively, since the submission of the FY2008 budget. Cost growth on CVN-78 required the Navy to program $1,394.9 million in cost-to-complete procurement funding for the ship in FY2014-FY2016 and FY2018 (see Table 1). As also shown in Table 2, however, cost growth on CVN-78, CVN-79, and CVN-80 more or less stopped in FY2013 and FY2014:

- while the estimated cost of CVN-78 grew considerably between the FY2008 budget (the budget in which CVN-78 was procured) and the FY2014 budget, since the FY2014 budget, it has grown by only a small amount (about 2%);

- while the estimated cost of CVN-79 grew considerably between the FY2008 budget and the FY2013 budget (in part because the procurement date for the ship was deferred by one year in the FY2010 budget),40 since the FY2013 budget it has declined by a small amount (less than 1%); and

- while the estimated cost of CVN-80 grew considerably between the FY2008 budget and the FY2013 budget (in part because the procurement date for the ship was deferred by two years in the FY2010 budget),41 since the FY2013 budget it has declined by about 11%.

Sources of Risk of Cost Growth and Navy Actions to Control Cost

Sources of risk of cost growth on CVN-78 have included, among other things, certain new systems to be installed on CVN-78 whose development, if delayed, could delay the completion of the ship. These systems include a new type of aircraft catapult called the Electromagnetic Launch System (EMALS), a new aircraft arresting system called the Advanced Arresting Gear (AAG), and the ship's primary radar, called the Dual Band Radar (DBR). Congress has followed these and other sources of risk of cost growth for years.

In July 2016, the DOD Inspector General issued a report critical of the Navy's management of the AAG development effort.42 In January 2017, it was reported that after conducting a review of potential alternative systems, the Navy had decided to continue stay with its plan to install EMALs and AAG on the first three Ford-class carriers.43 Section 125 of the FY2017 National Defense Authorization Act (S. 2943/P.L. 114-328 of December 23, 2016) limited the availability of funds for the AAG program until certain conditions are met.

Navy officials have stated that they are working to control the cost of CVN-79 by equipping the ship with a less expensive primary radar,44 by turning down opportunities to add features to the ship that would have made the ship more capable than CVN-78 but would also have increased CVN-79's cost, and by using a build strategy for the ship that incorporates improvements over the build strategy that was used for CVN-78. These build-strategy improvements, Navy officials have said, include the following items, among others:

- achieving a higher percentage of outfitting of ship modules before modules are stacked together to form the ship;

- achieving "learning inside the ship," which means producing similar-looking ship modules in an assembly line-like series, so as to achieve improved production learning curve benefits in the production of these modules; and

- more economical ordering of parts and materials including greater use of batch ordering of parts and materials, as opposed to ordering parts and materials on an individual basis as each is needed.

For additional background information on cost growth in the CVN-78 program, Navy efforts to stem that growth, and Navy efforts to manage costs so as to stay within the program's cost caps, see Appendix C and Appendix D.

Confidence Levels

The Navy states that its confidence levels for its estimated procurement costs (not including costs for class-wide spare parts) for CVNs 79, 80, and 81 are 36%, 22%, and 20% as of June 2019, respectively, meaning that the Navy as of June 2019 estimates that the risk of future cost growth on CVNs 79, 80, and 81 were 74%, 78%, and 80%, respectively.45

October 2019 Press Reports About $197 Million Cost Cap Increase

An October 25, 2019, press report stated:

The Navy's most expensive vessel is getting even costlier, as the service says it needs to add as much as $197 million more to correct deficiencies with the USS Gerald R. Ford aircraft carrier.

That includes completing the installation and certification of 11 elevators to lift munitions and other equipment from below decks that were supposed to be ready more than two years ago.

The previously undisclosed notification to Congress is on top of an extra $120 million identified in May 2018 to correct earlier deficiencies. The move last year caused the carrier to breach a $12.9 billion cost cap set by Congress in an effort to stop spiraling cost increases. The new request takes the carrier's estimated cost to $13.22 billion.

The latest funding is needed "to correct deficiencies identified during testing to ensure the safety of the ship and personnel and to deliver an operational ship to the fleet," Captain Danny Hernandez, a Navy spokesman, said in a statement….

More money also is needed to pay for "additional labor to address and correct technical issues, completing deferred work," and "there are also time charges associated with a longer repair period," the Pentagon comptroller said in an Oct. 7 document to Congress requesting permission for the Navy to shift $40 million from prior-year programs. The remaining $157 million would come from funds this fiscal year and 2021, Hernandez said.46

An October 28, 2019, press report stated: